CONSTRUCTION

CONSTRUCTION

Digital throughout

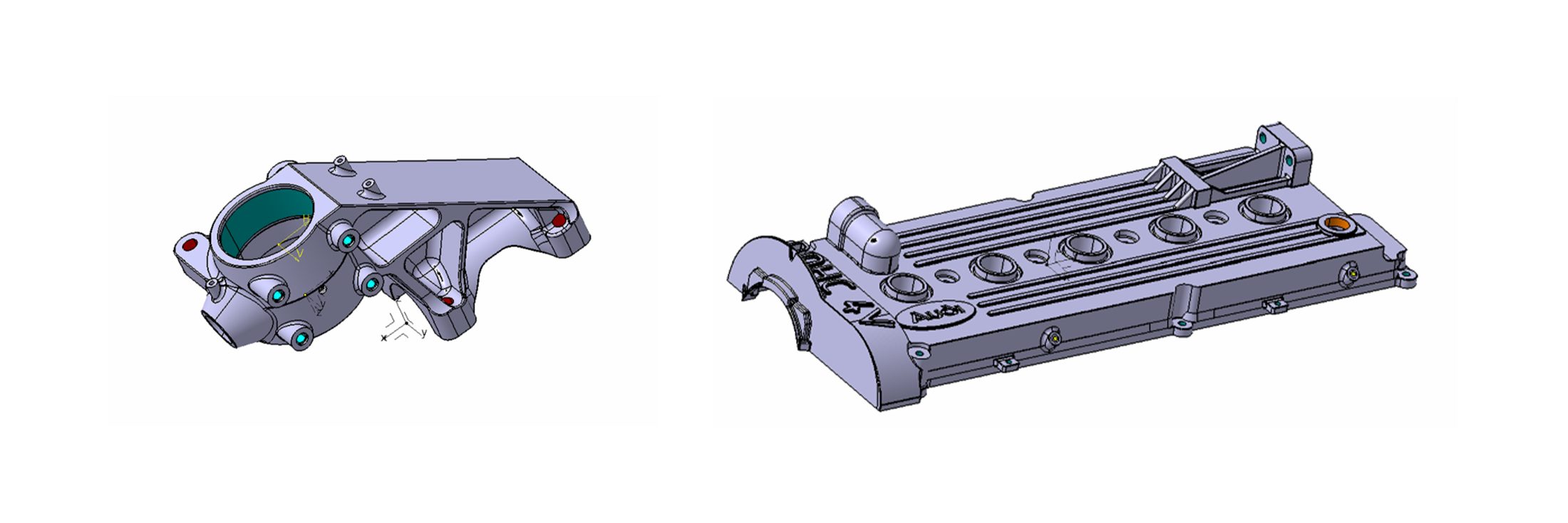

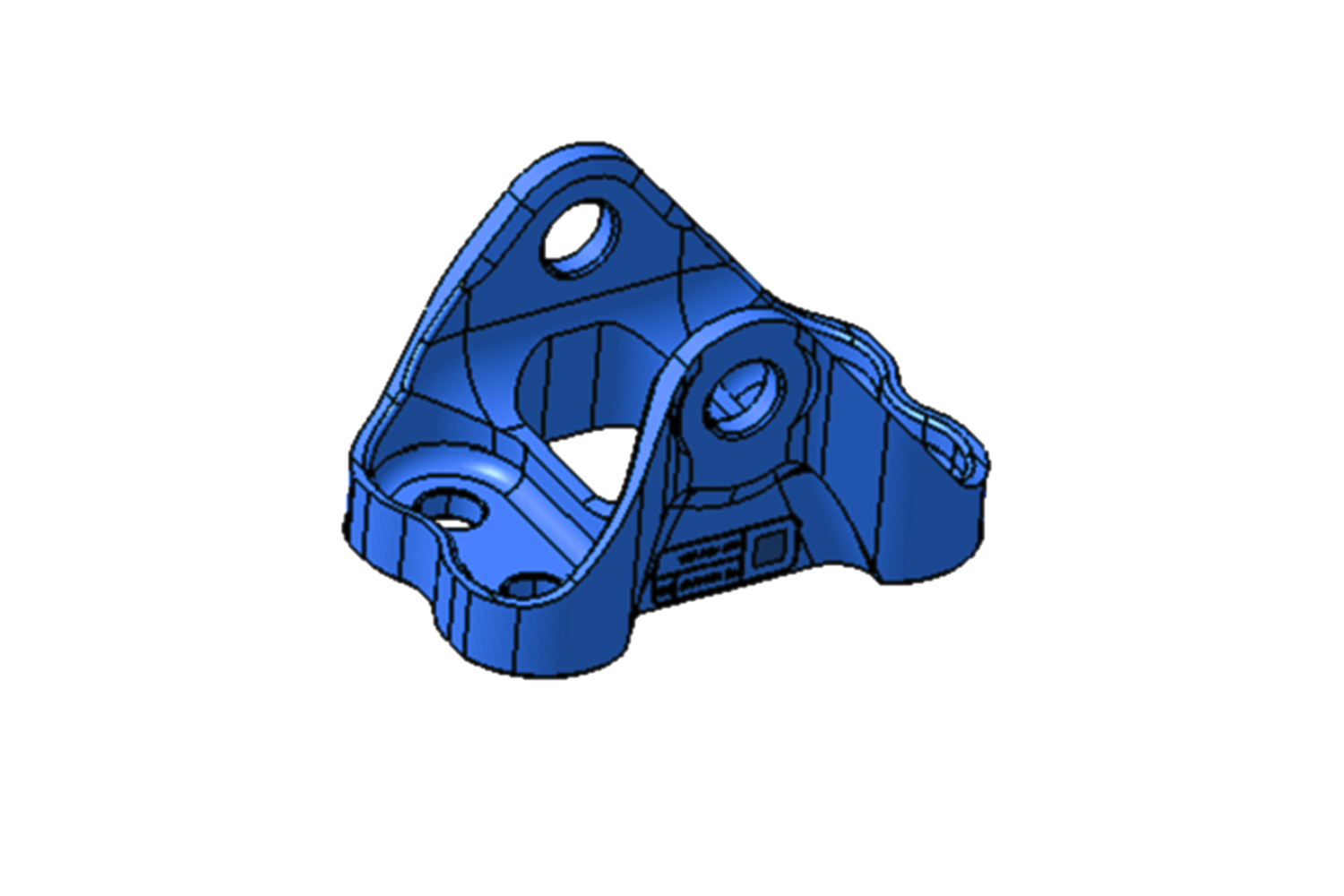

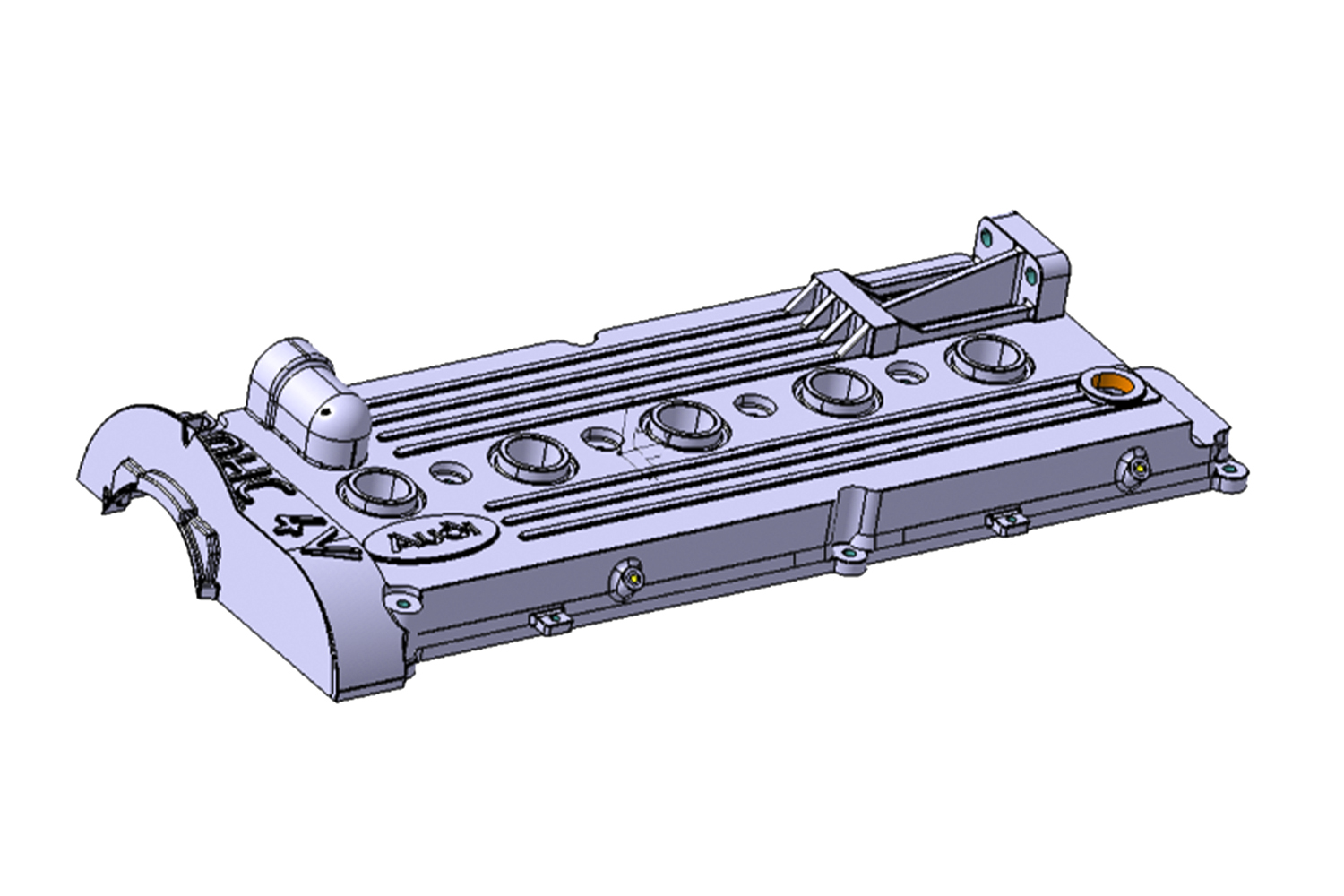

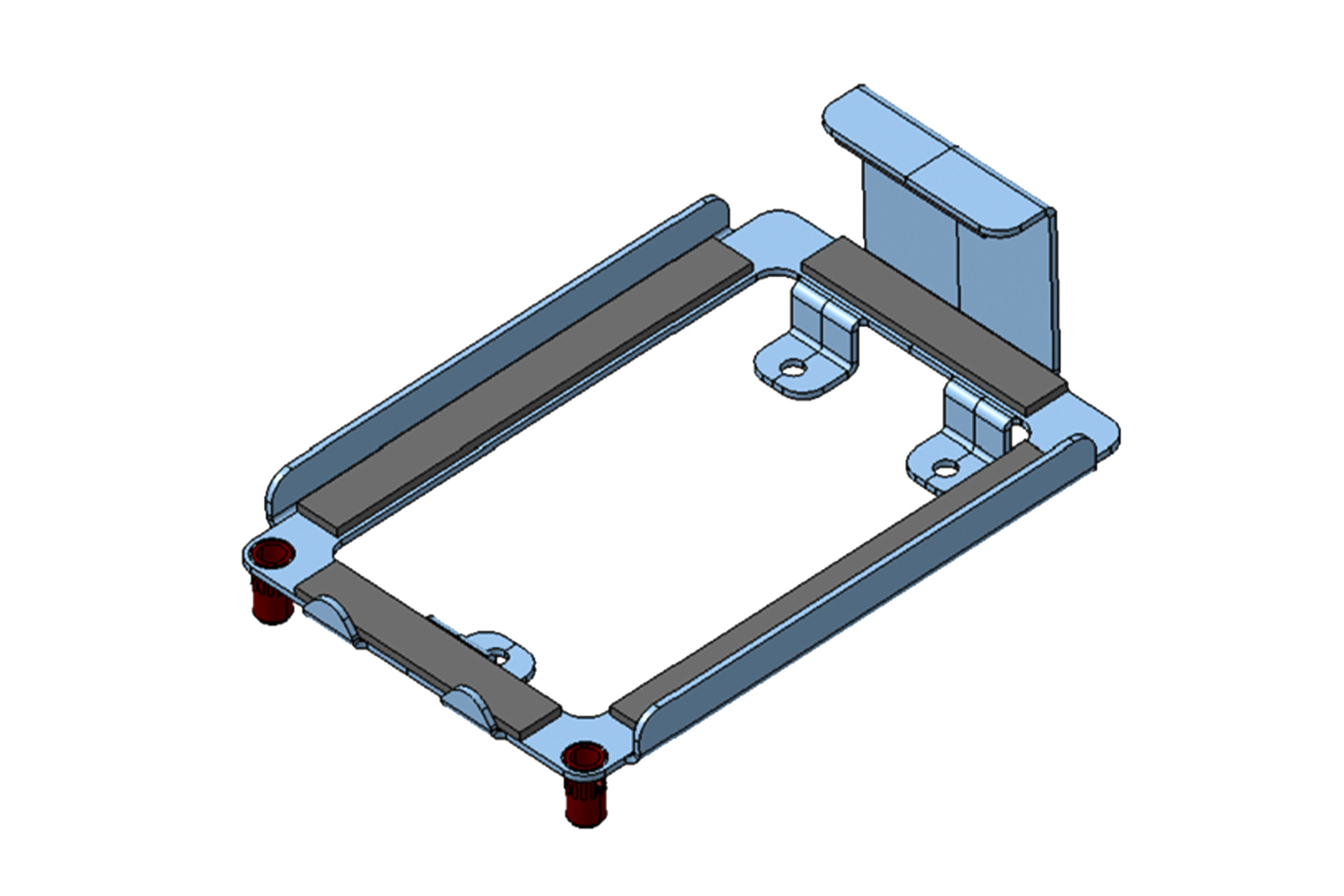

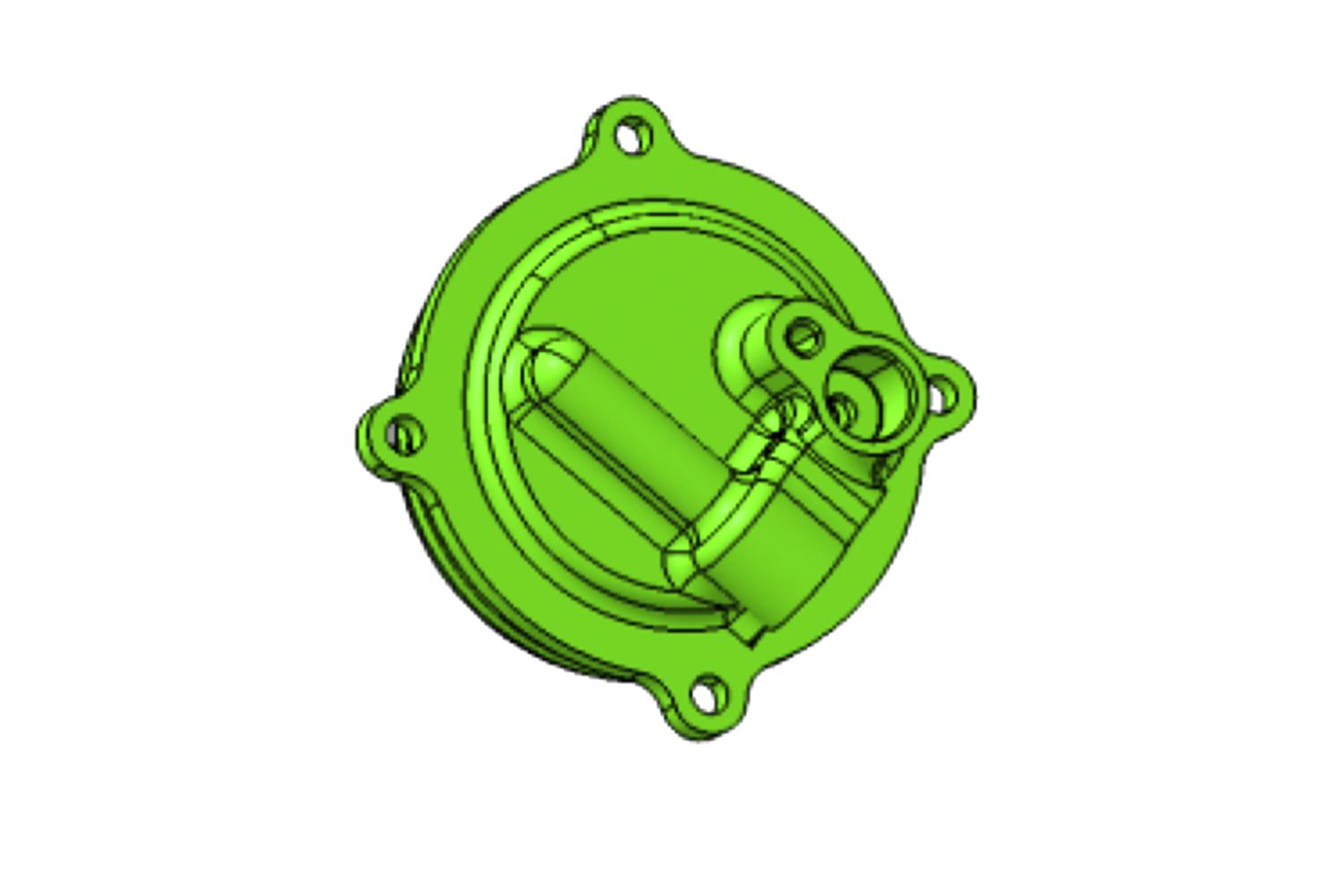

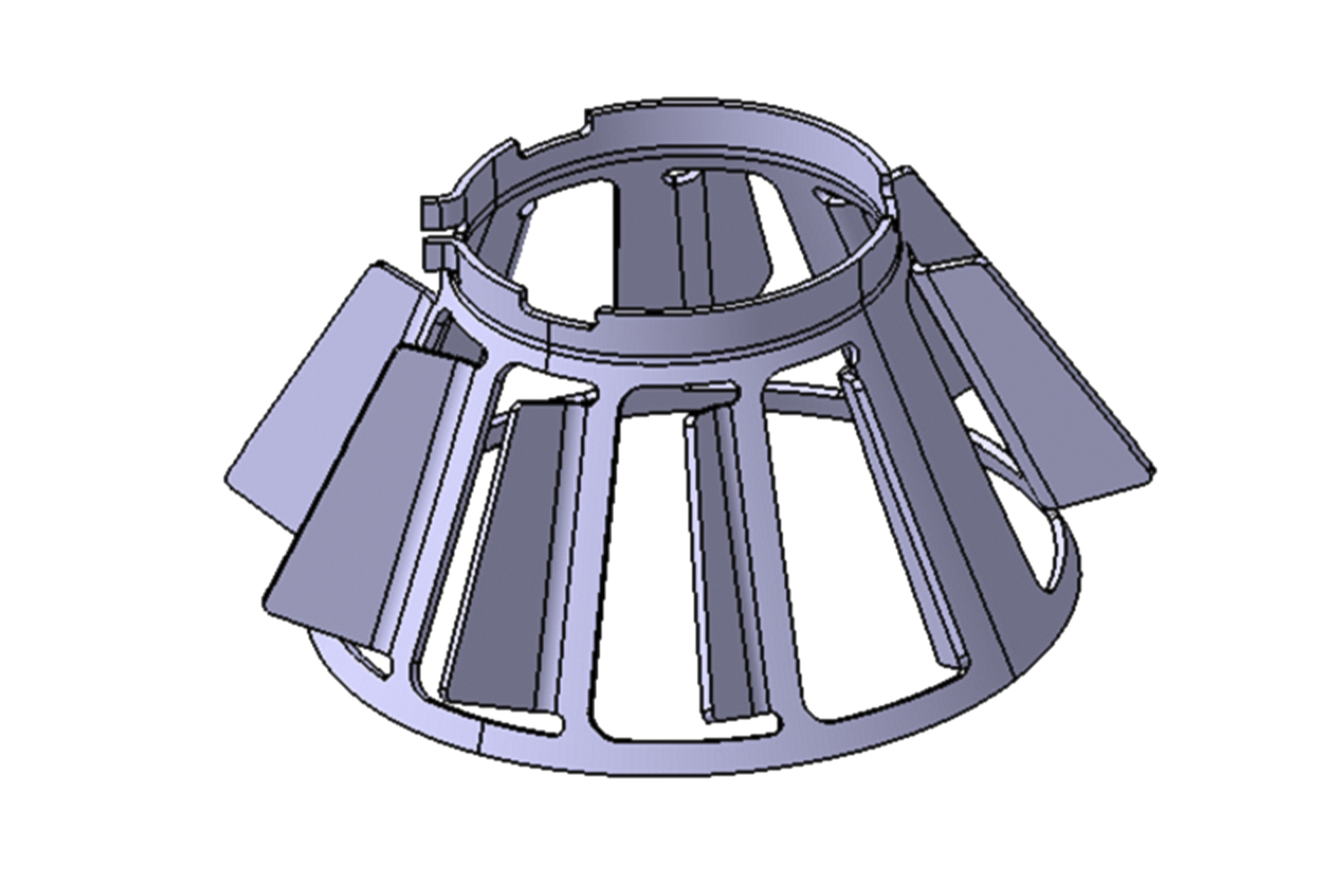

As a rule, the digital 3D component models of our customers serve as the starting point for our work, and we are happy to provide them with advice on the design of parts and components suitable for production.

Following a thorough examination of the shape and material of the templates, we define an efficient manufacturing sequence for the components. If, in individual cases, only physical component models are available, we can measure these using optical or tactile measuring machines and convert them into digital models.

Modern CAD/CAM workstations, the use of common software manufacturers (e.g. CATIA, TEBIS, WorkNC and Visi-CAD) and dren file formats (STP, Catpart, IGES, DXF) as well as data transfers (Odette, Engdax) ensure a safe and smooth workflow.

Technologie

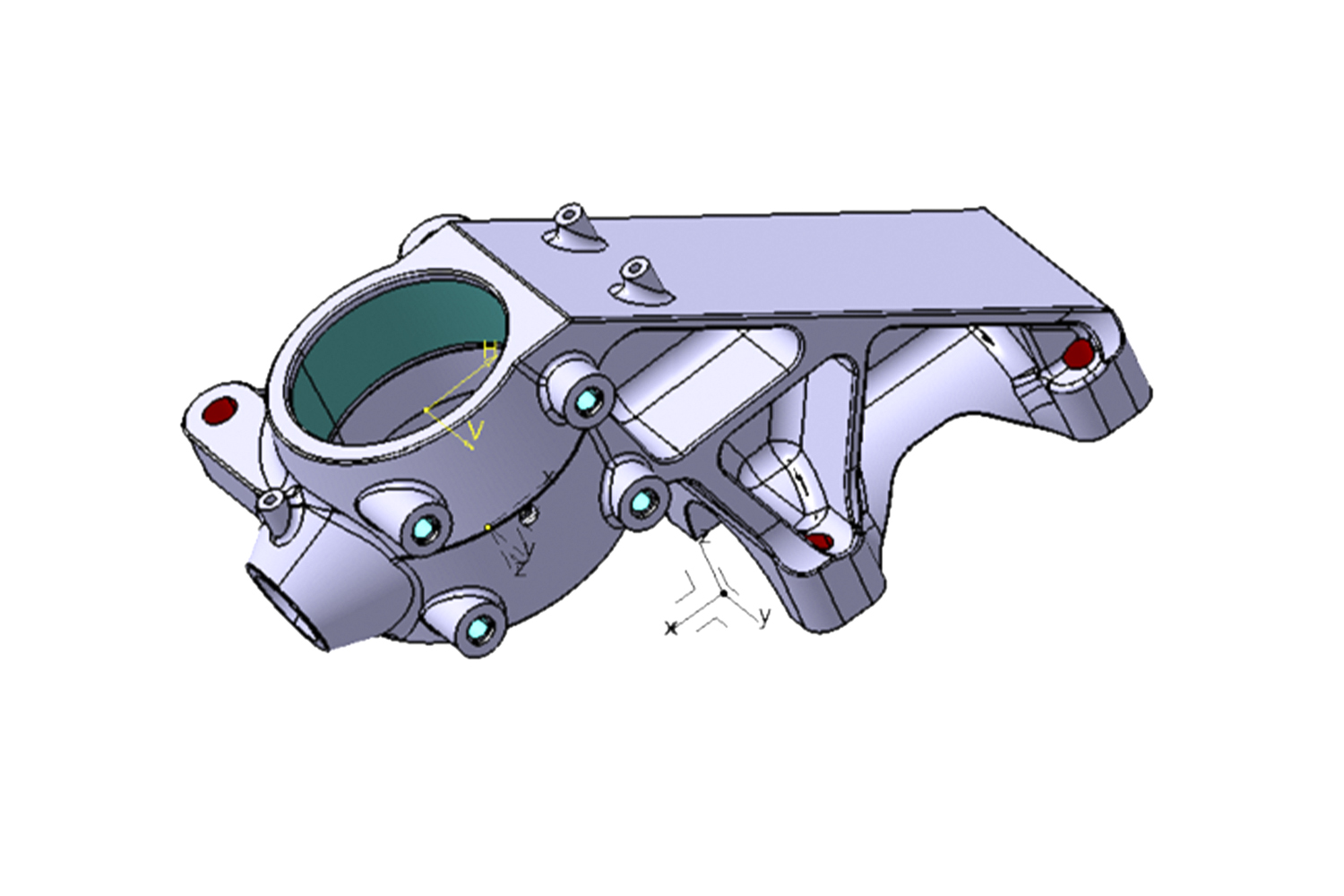

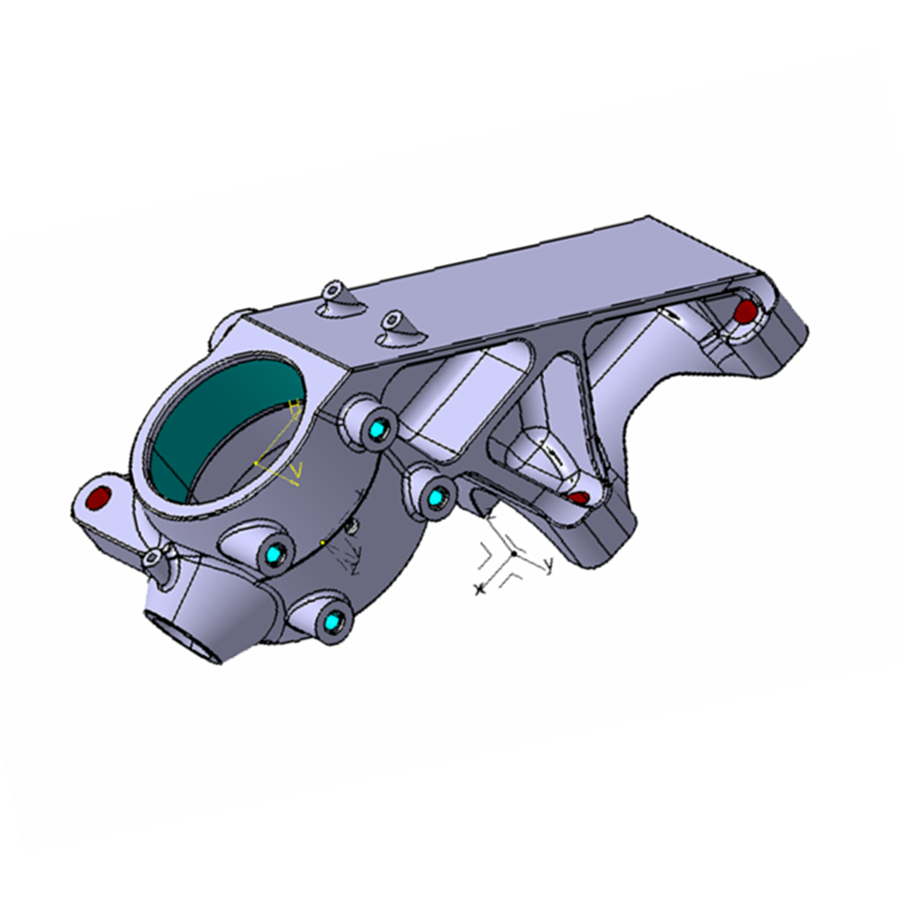

Task:

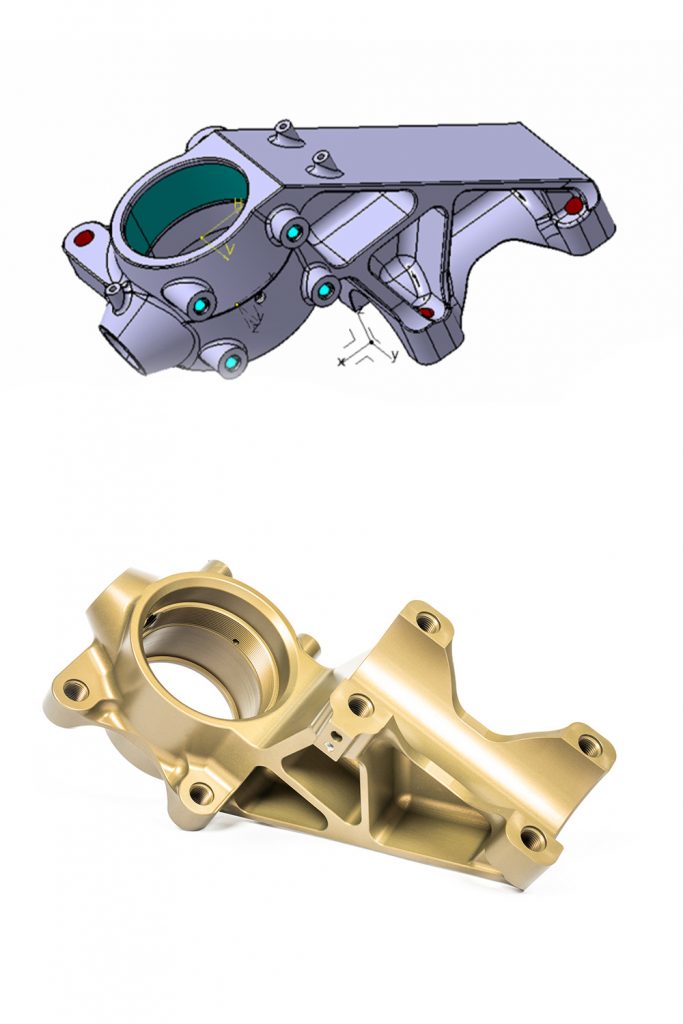

For our Race Car Manufaktur’s replica Audi Sport Quattro S1 E2, we developed a new wheel carrier based on an original component from the 1980s.

Challenge:

Better than the original – and at today’s state of the art.

Solution:

Using an optical 3D scanner, the first step was to digitize the original component. From this, we developed a design model that was used for load simulations and to optimize material thicknesses and qualities, and was also the starting point for programming our 5-axis machining centers. Final measurements were carried out with optical measuring equipment as a target/actual comparison.

EXAMPLES

OTHER COMPETENCIES

Prototyping

We supply products in near-series quality. With processes that anticipate series production and thus enable early inspections and test runs. With a high vertical range of manufacture that ensures short delivery times.

Forming Technology

We provide the desired shape. With project-specific molds and fixtures as well as hydraulic- and deep-drawing presses that enable the precise molding of even complex components.

Laser Technology

We cut and weld with short lead times. With large powerful 5-axis laser cutting machines that ensure consistent high quality when processing sheets of different materials and thicknesses.

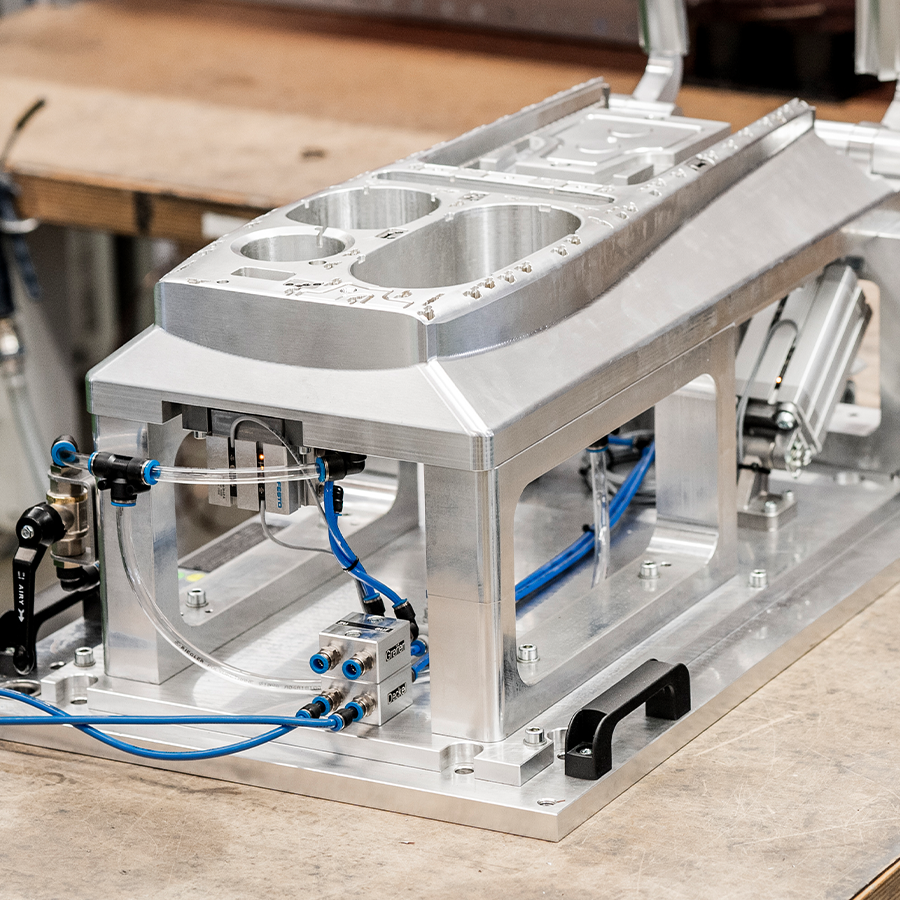

Toolmaking

We develop tools and fixtures adapted to the project requirements. For exceptionally precise components with flatnesses of ± 3 µm, parallelism of < 1/100 and surface finishes of Rz 2.

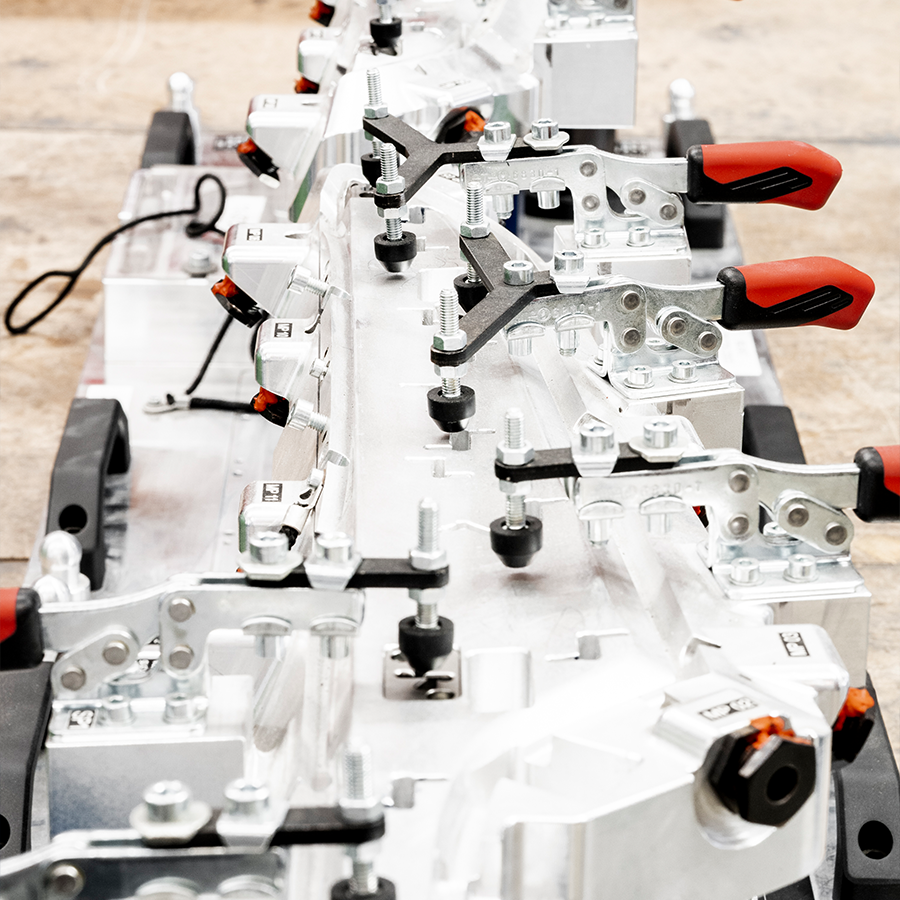

Gauge construction

We are precise and manufacture measuring fixtures as well as inspection gauges and equipment made of steel, aluminum and lightweight materials. For precise recording and inspection of components.

Construction

We work digitally. With modern CAD/CAM workstations, secure data transfers and all common software formats. For a production-oriented and efficient manufacturing sequence of parts and components.