TOOLMAKING

TOOLMAKING

Manufacture individually

The production of high-precision components requires high-precision and not infrequently also highly complex tools and devices. We usually manufacture these ourselves – in particular with our currently 18 CNC-controlled 3- or 5-axis milling machines as well as with various conventional and CNC-controlled lathes.

However, an essential resource for the production of first-class workpieces with outstanding properties are also the many years of experience of our employees, their craftsmanship, their willingness to experiment and their ability to improvise.

The interaction of people and machines results in components with flatnesses of ± 3 µm, a parallelism of < 1/100, a surface quality of Rz 2 – and this in repeat accuracies with values < 1/100 mm. Downstream processing steps such as grinding and eroding can thus often be omitted.

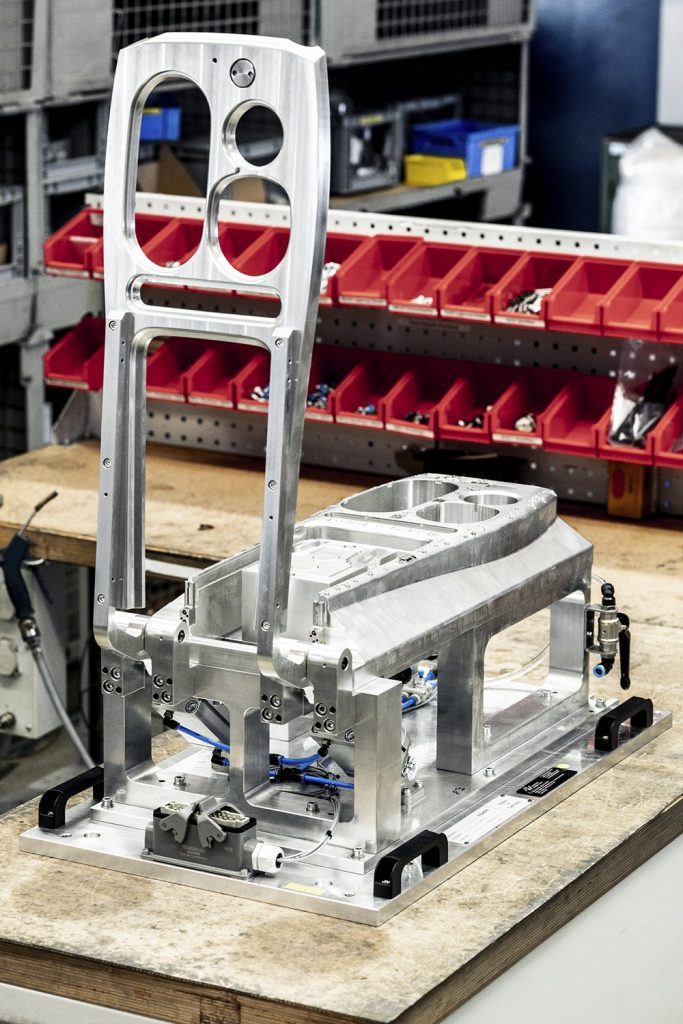

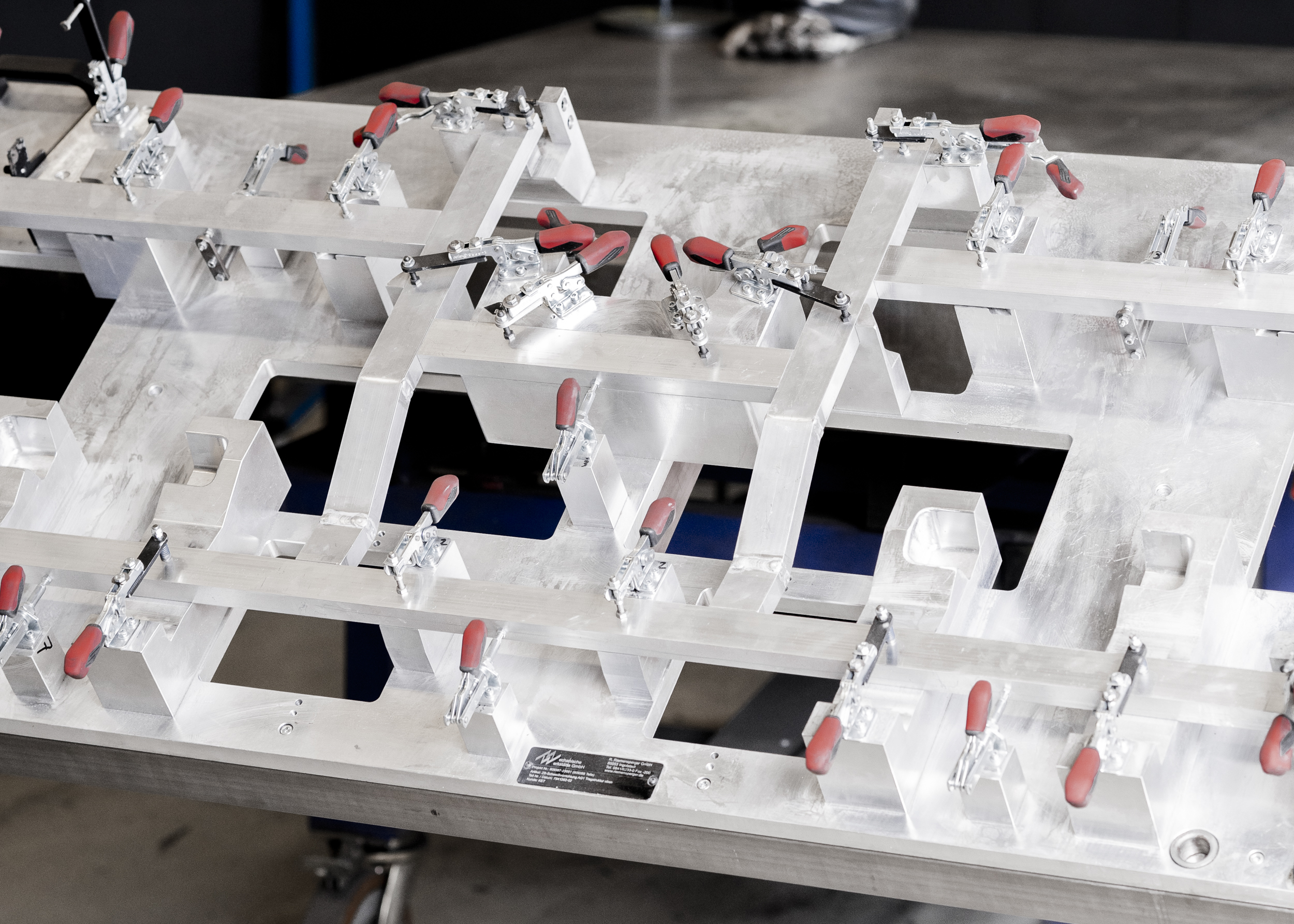

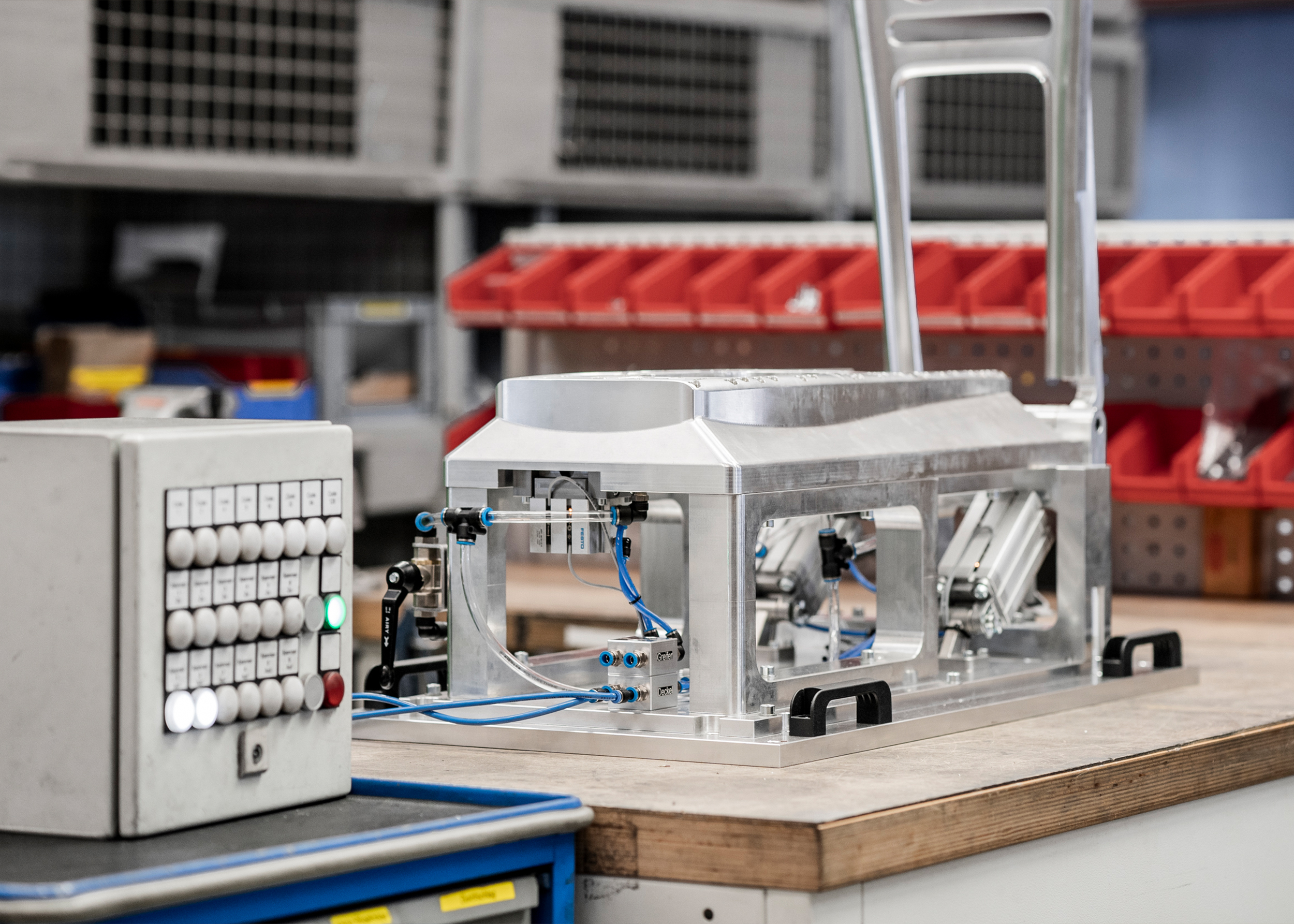

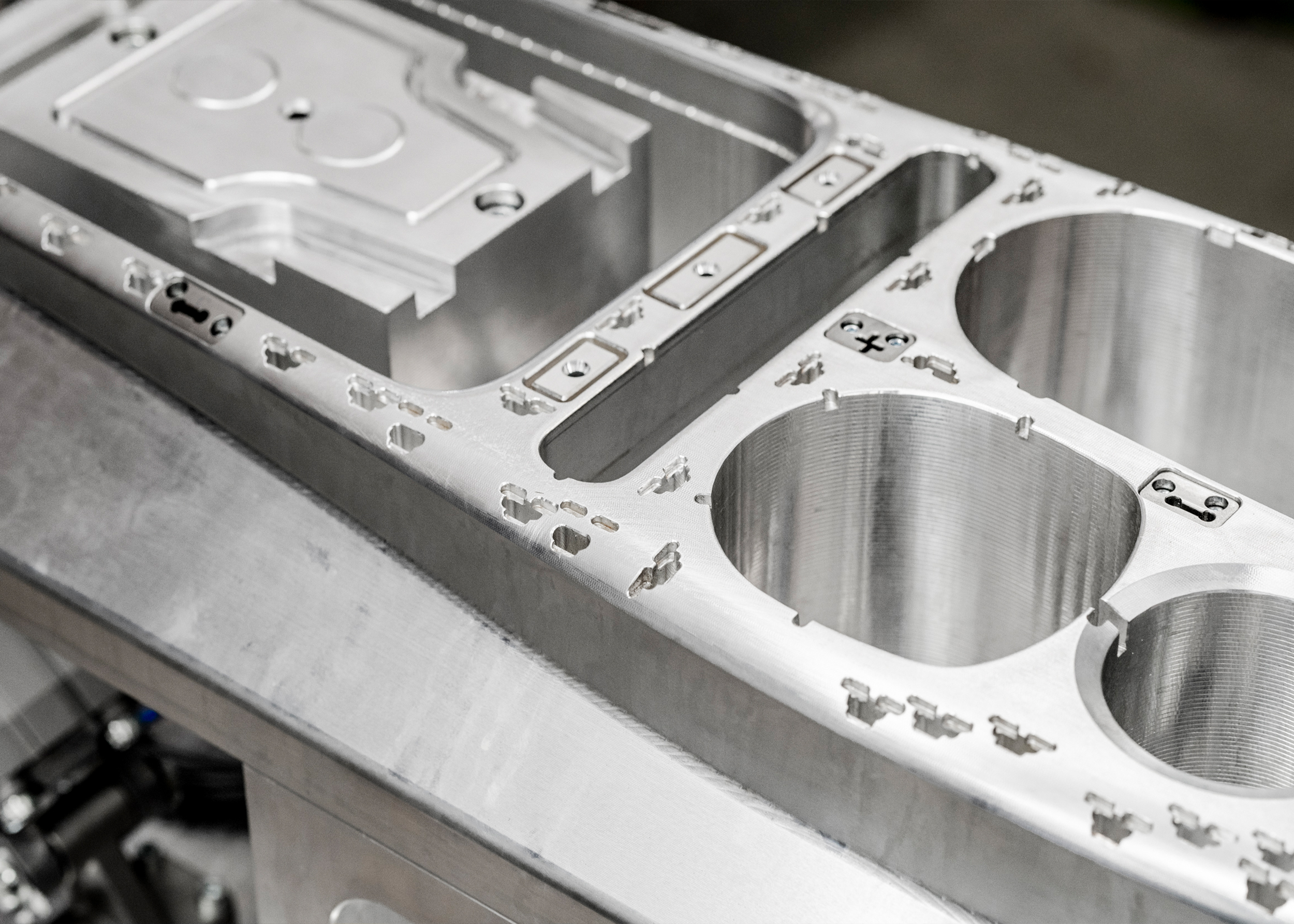

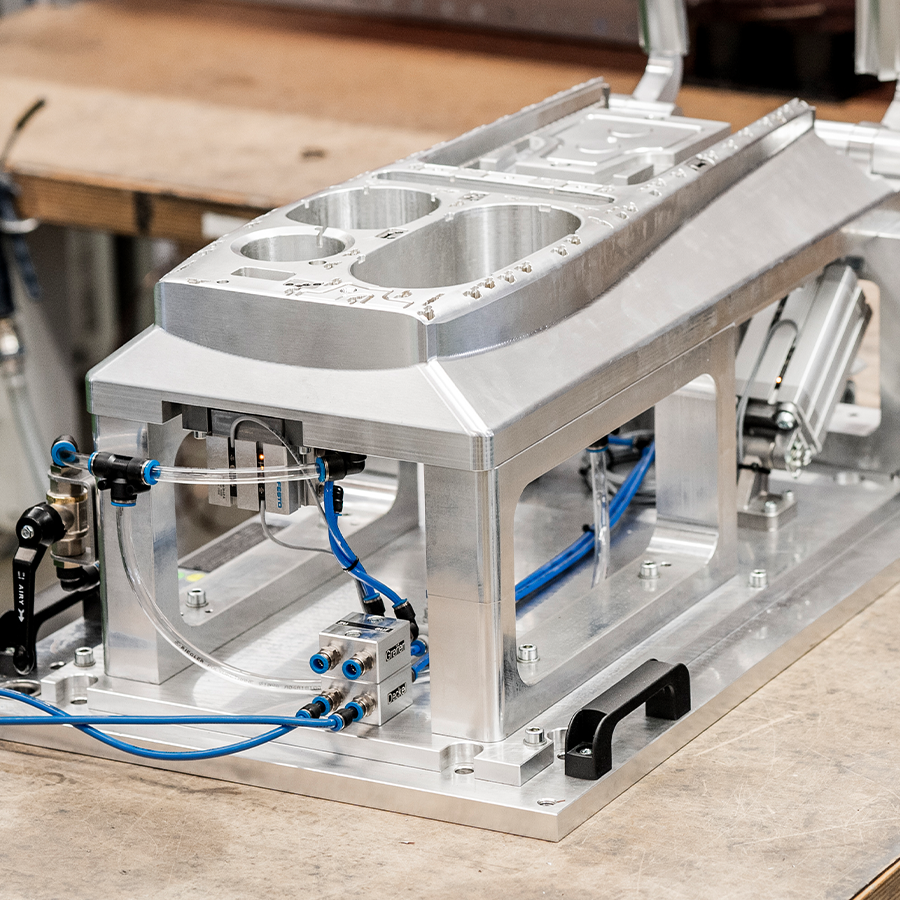

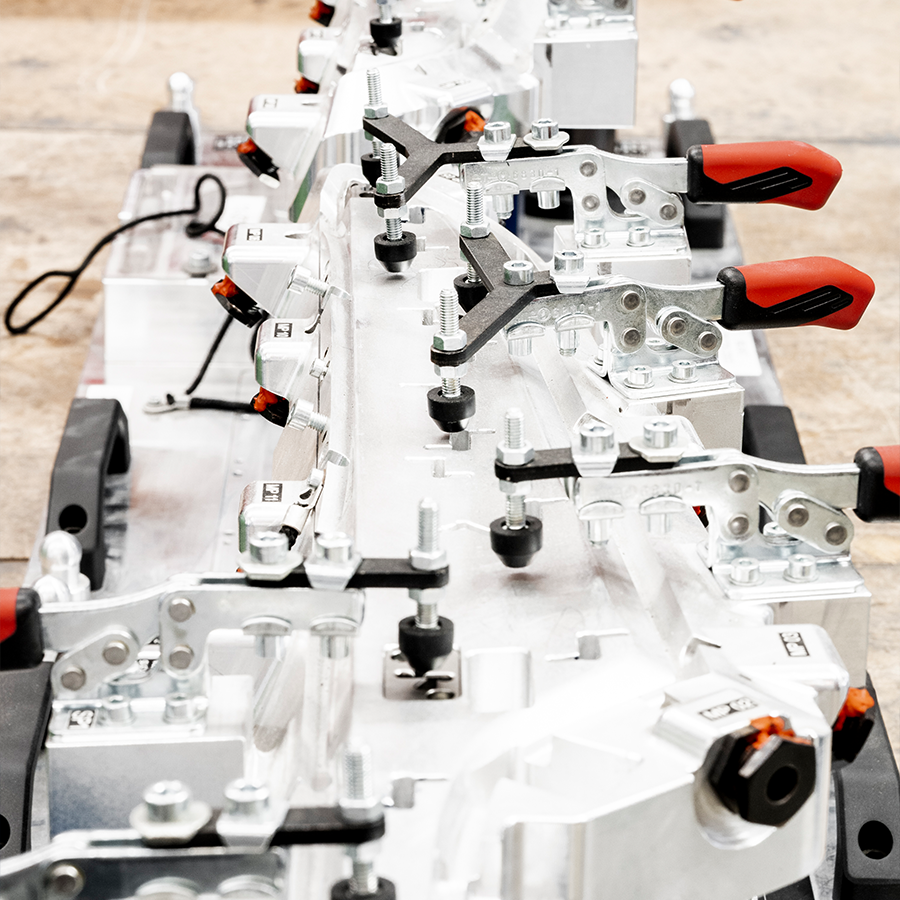

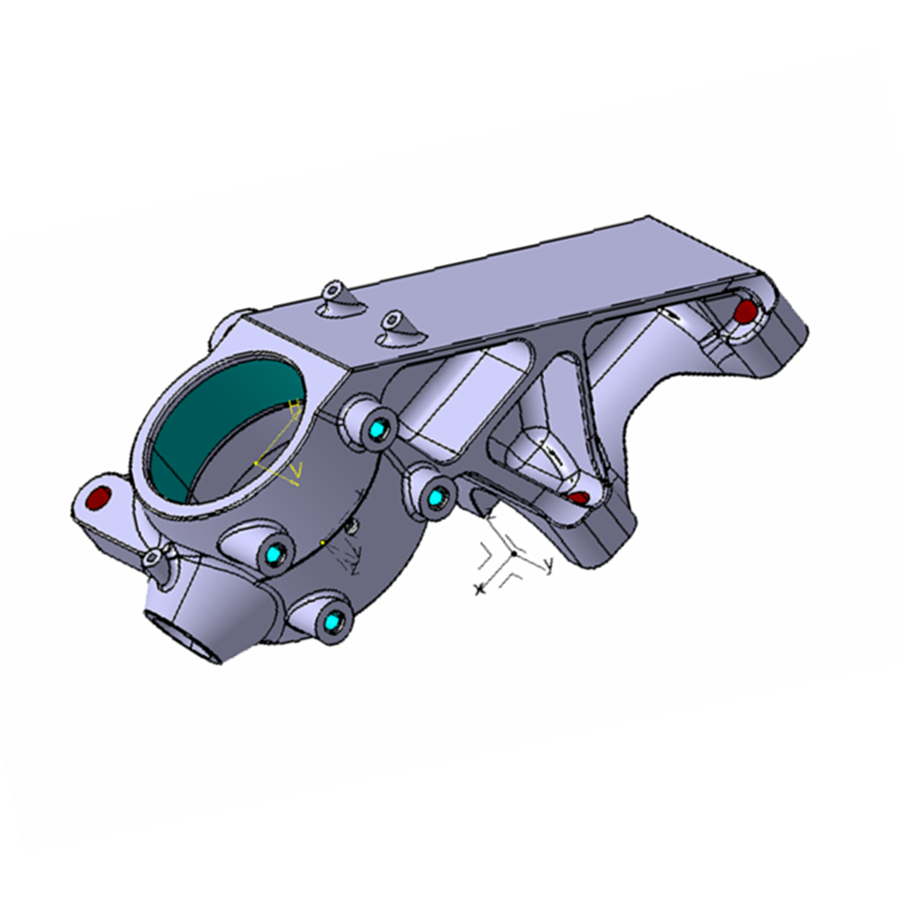

Manufacturing example: milling device

Task:

Design and build a milling device that can automate the finishing of the raw edges of plastic injection-molded parts with high precision and give them their final shape.

Challenge:

Simple fixing of the components with tolerances as low as ± 0.05 mm.

Solution:

The parts are pre-fixed by means of vacuum and firmly clamped with a pneumatic clamping device. For reasons of durability, the centering elements on the top of the fixture are firmly incorporated into the aluminum body as steel built-in parts. A 24-pin plug-in connection serves as the interface between the milling device and the milling machine.

EXAMPLES

OTHER COMPETENCIES

Prototyping

We supply products in near-series quality. With processes that anticipate series production and thus enable early inspections and test runs. With a high vertical range of manufacture that ensures short delivery times.

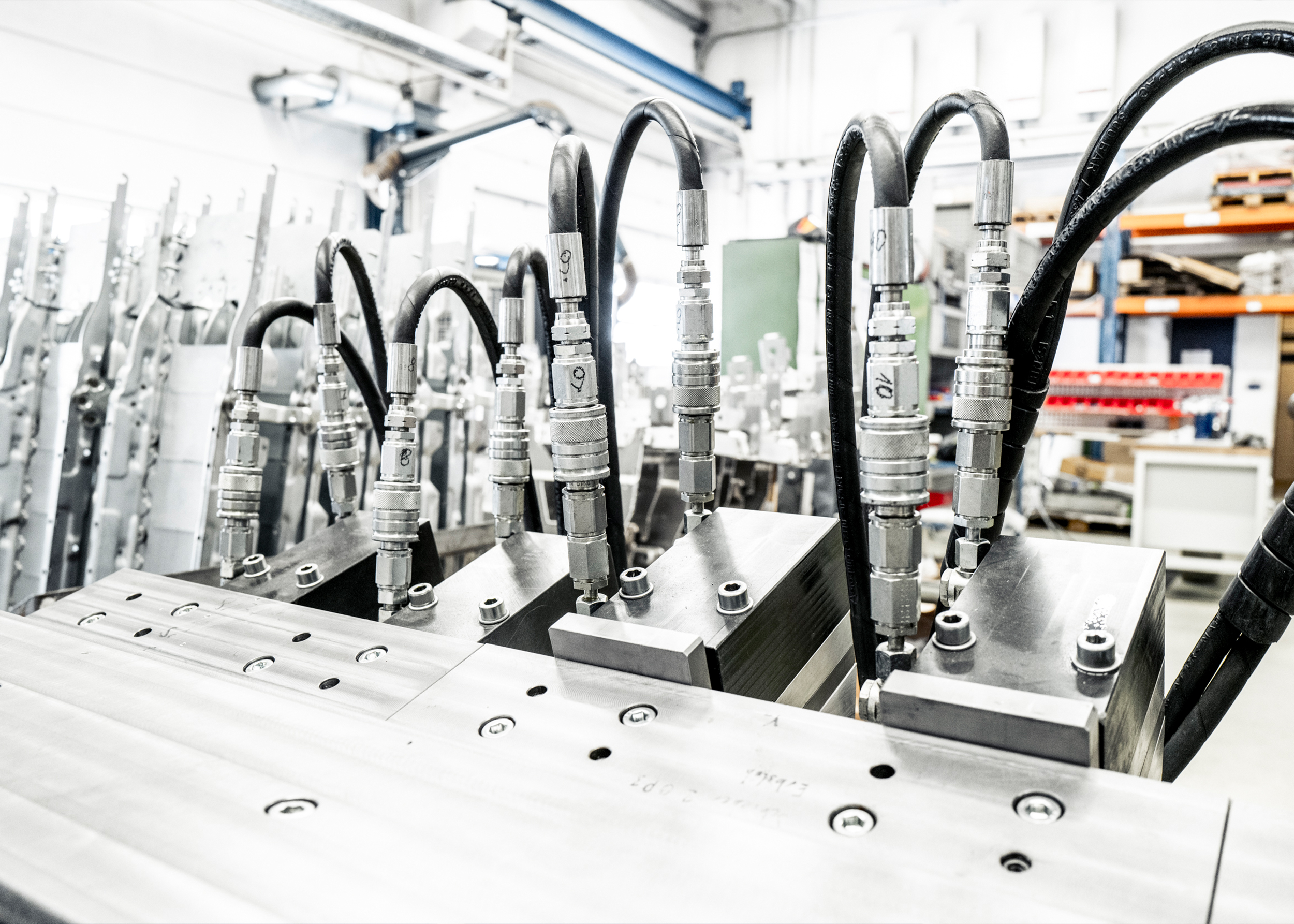

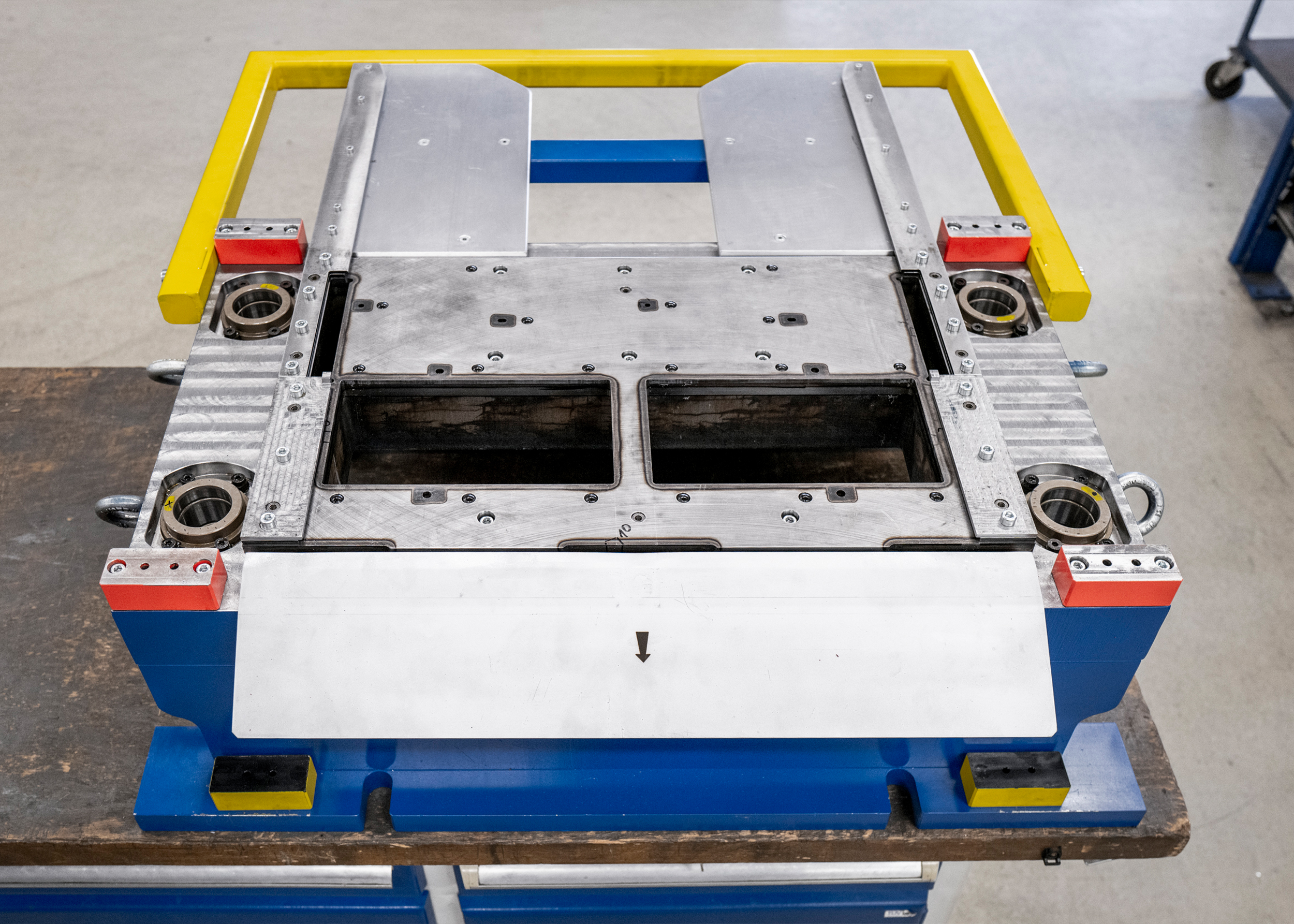

Forming Technology

We provide the desired shape. With project-specific molds and fixtures as well as hydraulic- and deep-drawing presses that enable the precise molding of even complex components.

Laser Technology

We cut and weld with short lead times. With large powerful 5-axis laser cutting machines that ensure consistent high quality when processing sheets of different materials and thicknesses.

Toolmaking

We develop tools and fixtures adapted to the project requirements. For exceptionally precise components with flatnesses of ± 3 µm, parallelism of < 1/100 and surface finishes of Rz 2.

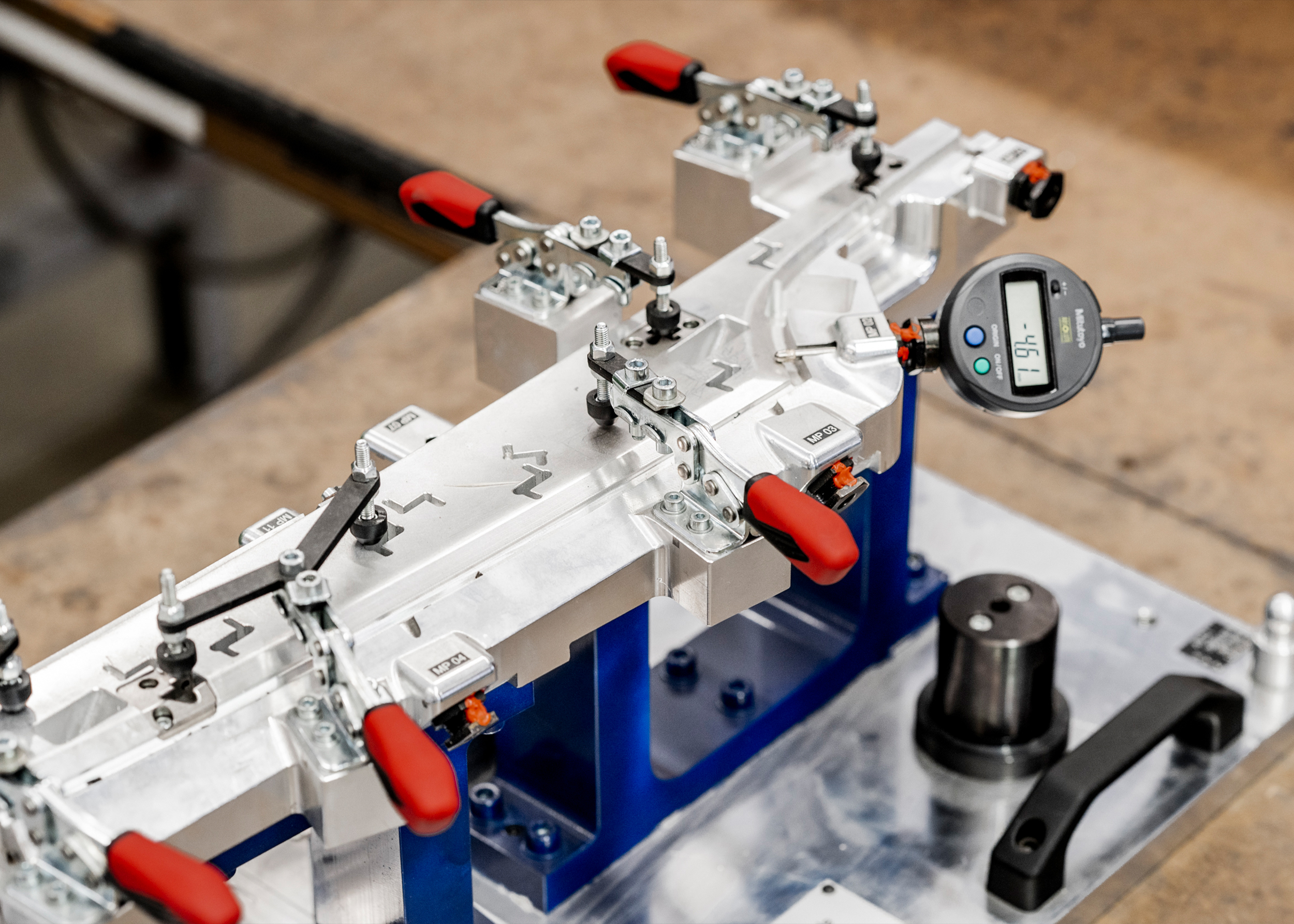

Gauge construction

We are precise and manufacture measuring fixtures as well as inspection gauges and equipment made of steel, aluminum and lightweight materials. For precise recording and inspection of components.

Construction

We work digitally. With modern CAD/CAM workstations, secure data transfers and all common software formats. For a production-oriented and efficient manufacturing sequence of parts and components.