COMPETENCIES

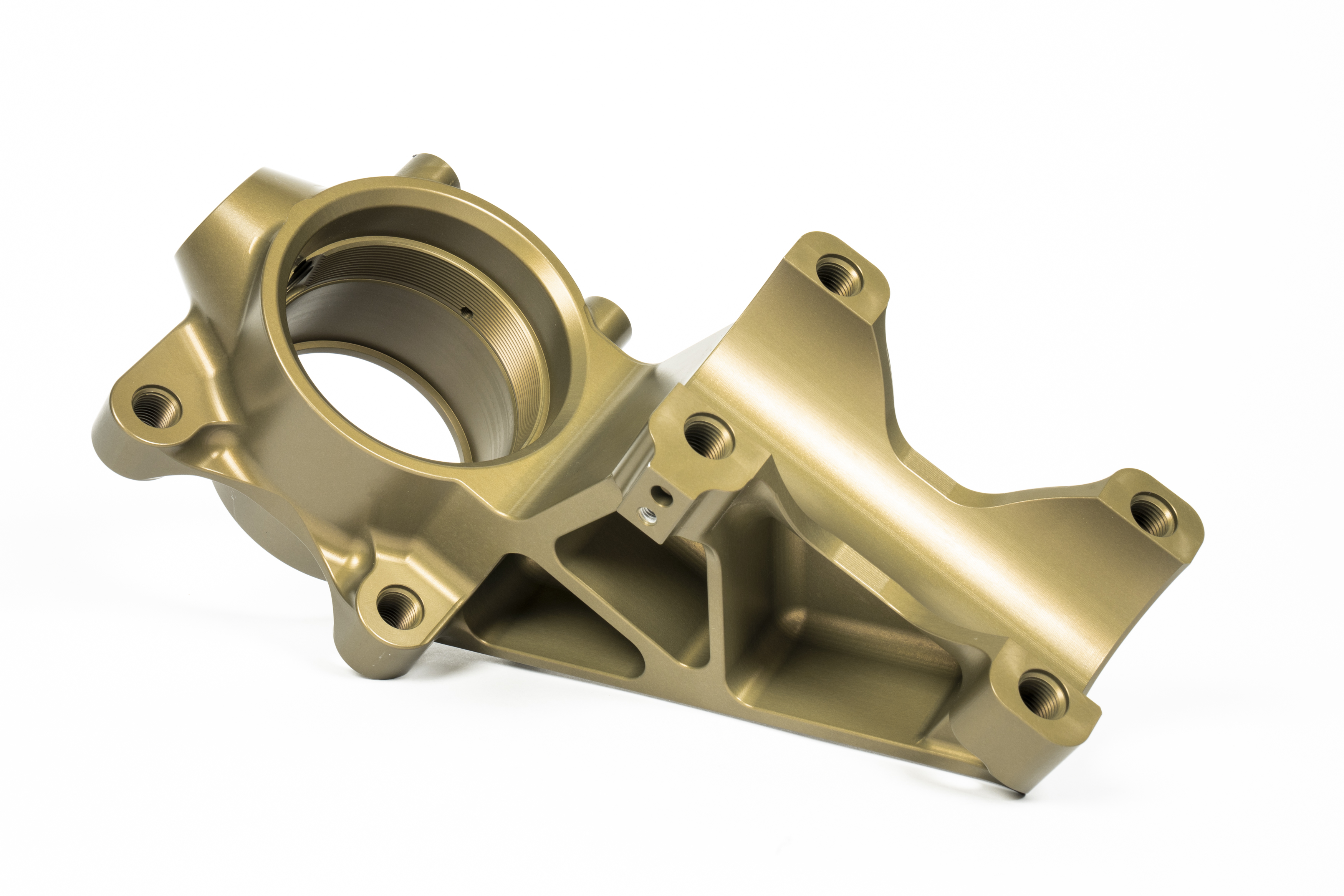

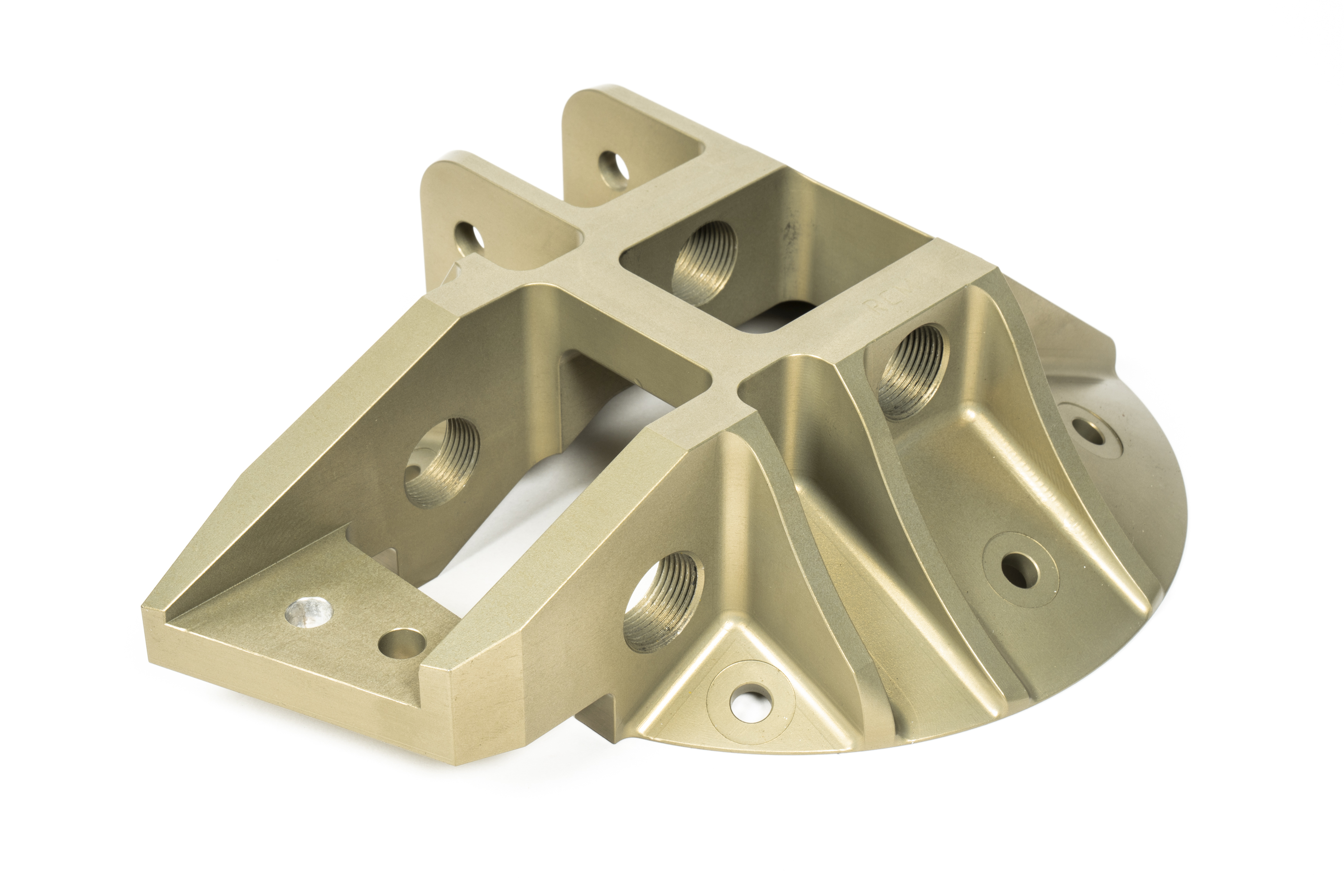

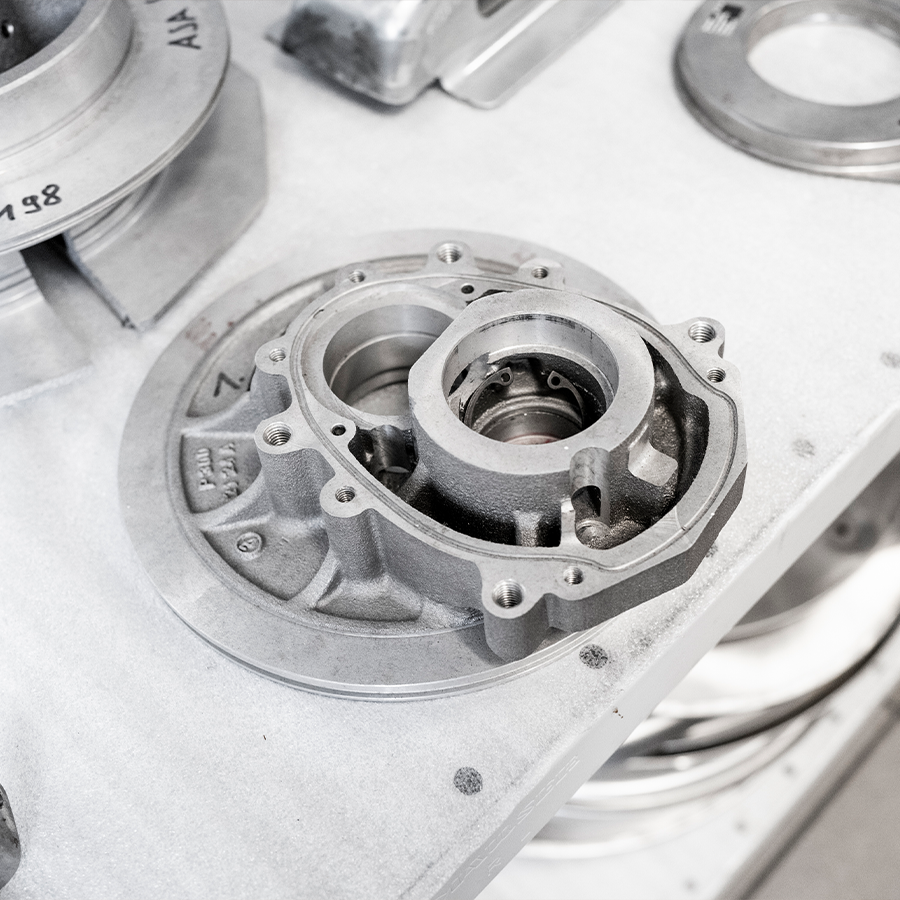

Prototyping

We supply products in near-series quality. With processes that anticipate series production and thus enable early inspections and test runs. With a high vertical range of manufacture that ensures short delivery times.

Forming Technology

We provide the desired shape. With project-specific molds and fixtures as well as hydraulic- and deep-drawing presses that enable the precise molding of even complex components.

Laser Technology

We cut and weld with short lead times. With large powerful 5-axis laser cutting machines that ensure consistent high quality when processing sheets of different materials and thicknesses.

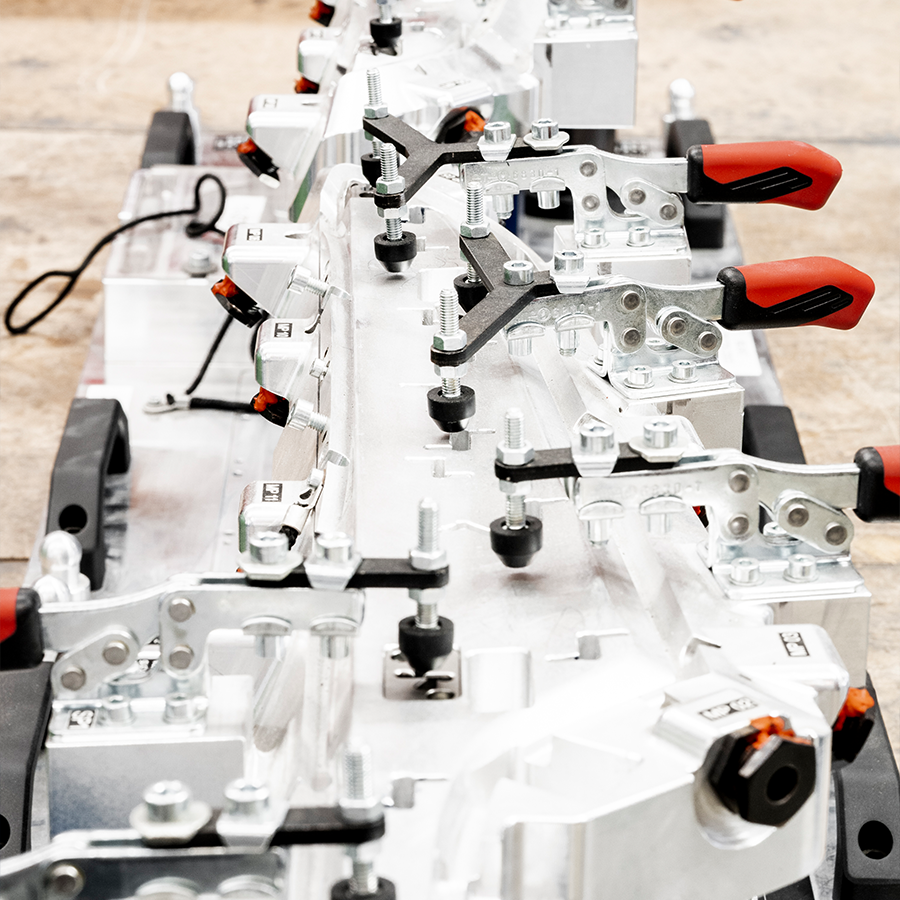

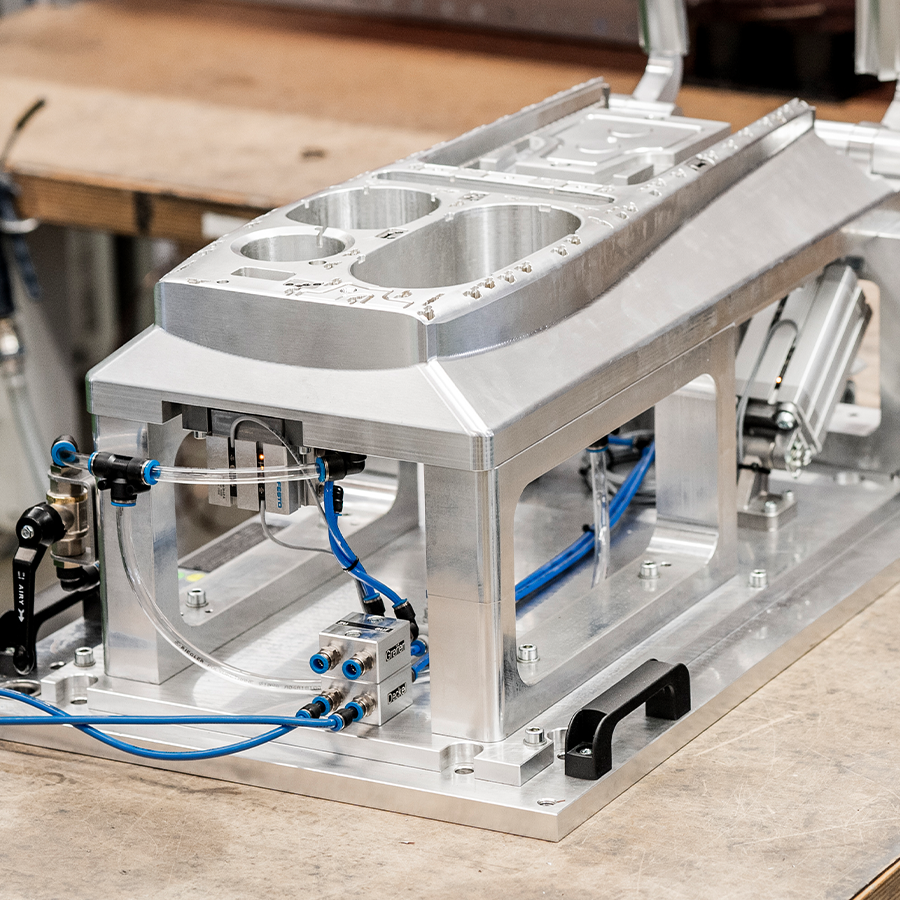

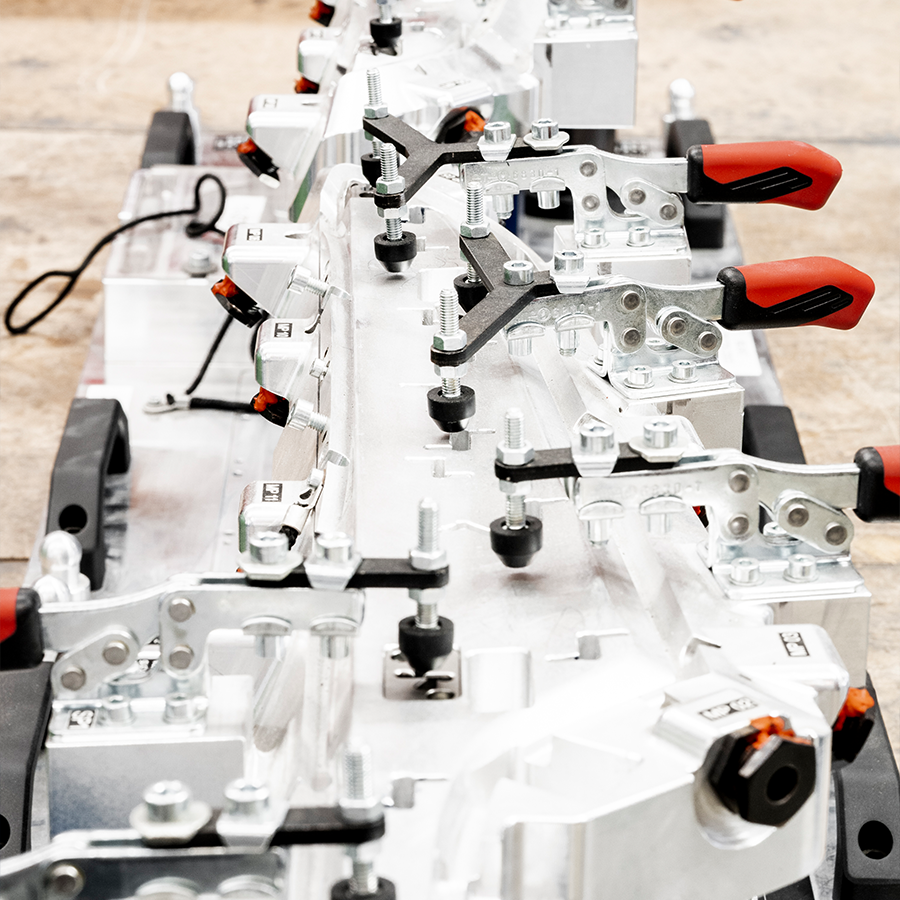

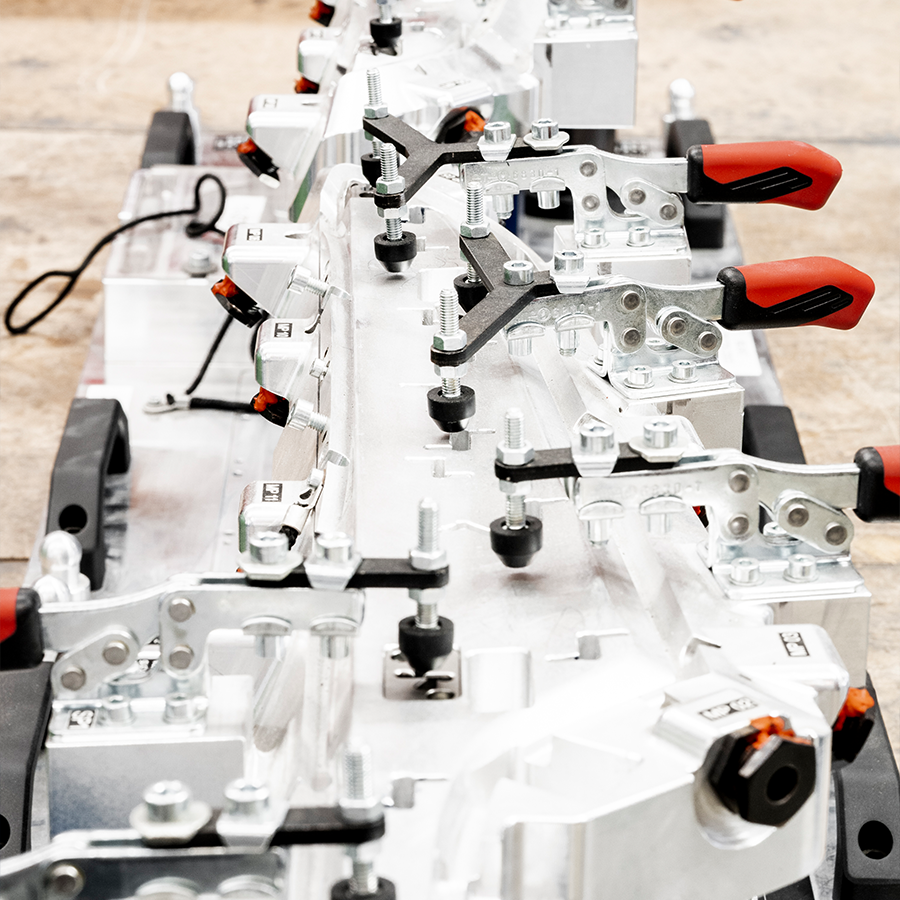

Toolmaking

We develop tools and fixtures adapted to the project requirements. For exceptionally precise components with flatnesses of ± 3 µm, parallelism of < 1/100 and surface finishes of Rz 2.

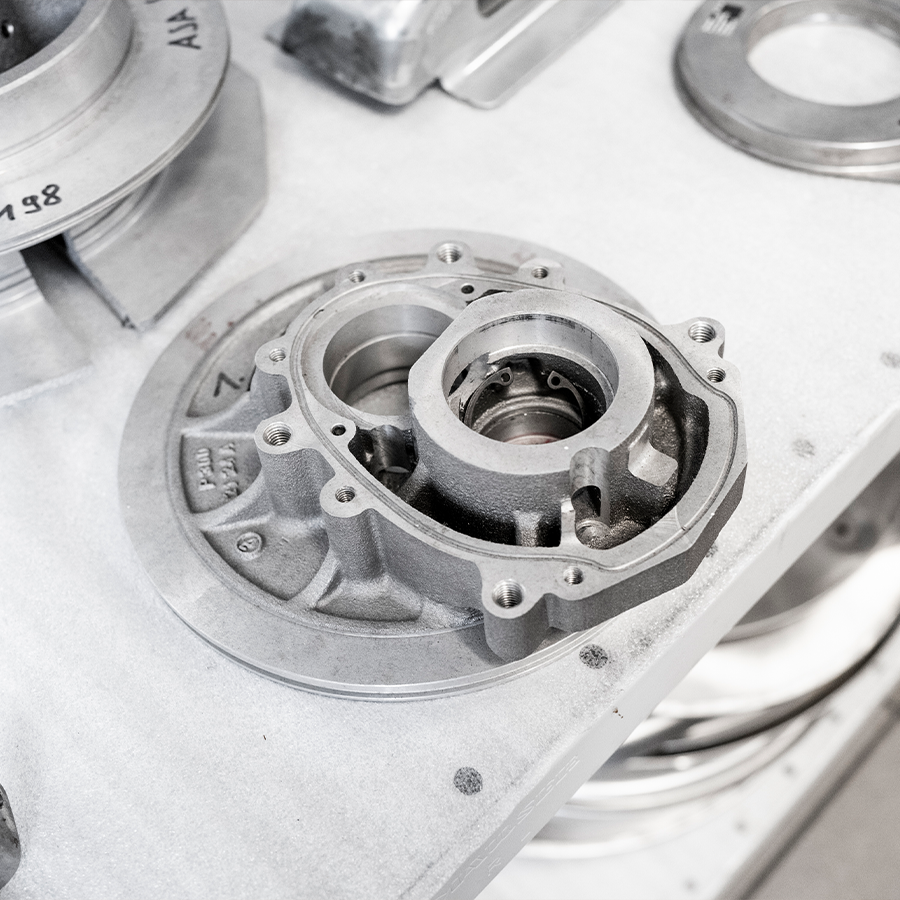

Gauge construction

We are precise and manufacture measuring fixtures as well as inspection gauges and equipment made of steel, aluminum and lightweight materials. For precise recording and inspection of components.

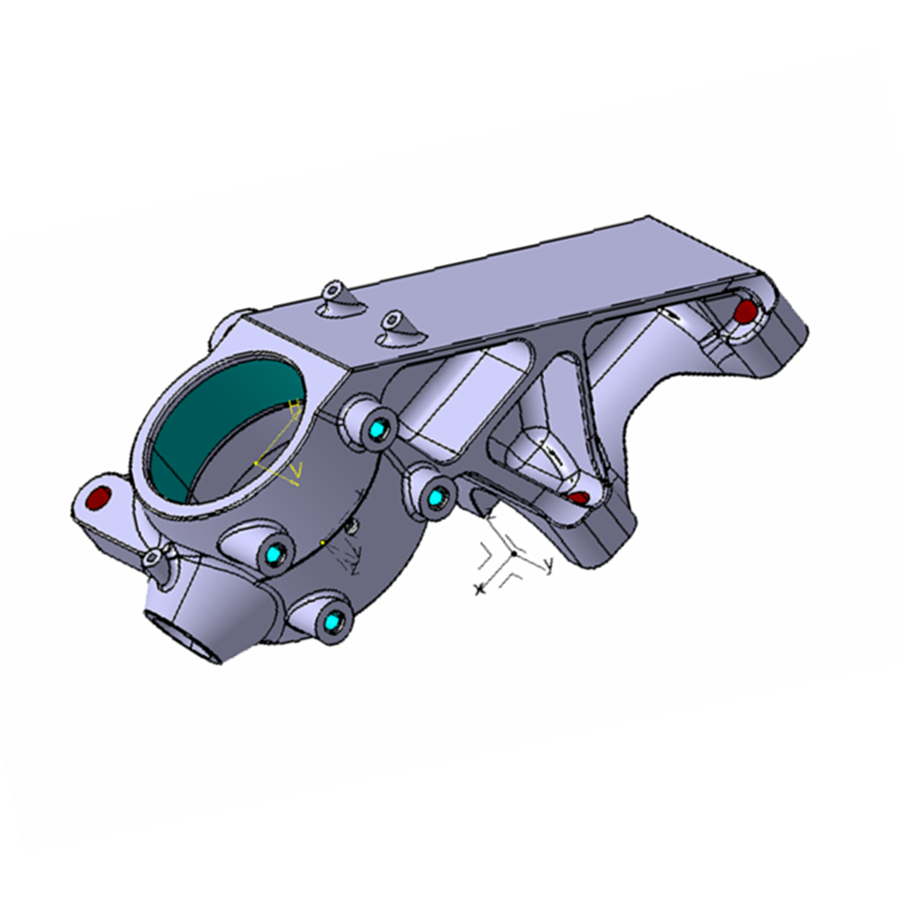

Construction

We work digitally. With modern CAD/CAM workstations, secure data transfers and all common software formats. For a production-oriented and efficient manufacturing sequence of parts and components.

PARTNER OF THE INDUSTRY

Our craftsmanship and technical experience, our detailed analyses of process parameters and our great willingness to experiment offer clear advantages to industrial customers: improved product quality and more efficient processes, but also potential savings on tools, fixtures, components and component groups.

We produce individual parts, create functional models and develop prototypes, pre-series and small series – in the following industries, among others: Automotive, motorsports, semiconductor and solar technology, household appliances, medicine, aerospace, crude oil production, composites, paper finishing and food.

In addition, we plan and implement customized automation and special equipment to increase the efficiency of series processes and new production tasks. The processing of the following materials, among others, is part of our daily routine: non-ferrous metals, titanium, plastics, high-strength materials, quartz and composite materials.

CAR MANUFACTURING

Our many years of technical know-how and our passion for automotive engineering formed the starting point for the founding of Race Car Manufaktur GmbH 8 years ago.

Here we handcraft replicas of the legendary Audi Sport Quattro S1 E2, with which Walter Röhrl made racing history 35 years ago. With great attention to detail, unmistakable, fully developed race cars are created, which are only delivered to enthusiasts all over the world after a thorough personal inspection by Walter Röhrl.

SCULPTURE BUILDING

With the help of powerful laser measuring machines, we are able to digitize any object brought into play by our customers – regardless of whether the original is a piece of jewelry, furniture or an airplane.

From the measurement data we obtain through this data feedback, we create abstracted reliefs as well as true-to-original or scaled-down 3D sculptures up to the size of a complete automobile, depending on the customer’s wishes. Materials available include aluminum, steel, copper and quartz glass.

INDUSTRIAL PARTNER

Our craftsmanship and technical experience, our detailed analyses of process parameters and our great willingness to experiment offer clear advantages to industrial customers: improved product quality and more efficient processes, but also potential savings on tools, fixtures, components and component groups.

We produce individual parts, create functional models and develop prototypes, pre-series and small series – in the following industries, among others: Automotive, motorsports, semiconductor and solar technology, household appliances, medicine, aerospace, crude oil production, composites, paper finishing and food.

In addition, we plan and implement customized automation and special equipment to increase the efficiency of series processes and new production tasks. The processing of the following materials, among others, is part of our daily routine: non-ferrous metals, titanium, plastics, high-strength materials, quartz and composite materials.

CAR MANUFACTURING

Our many years of technical know-how and our passion for automotive engineering formed the starting point for the founding of Race Car Manufaktur GmbH 8 years ago.

Here we handcraft replicas of the legendary Audi Sport Quattro S1 E2, with which Walter Röhrl made racing history 35 years ago. With great attention to detail, unmistakable, fully developed race cars are created, which are only delivered to enthusiasts all over the world after a thorough personal inspection by Walter Röhrl.

SCULPTURE BUILDING

With the help of powerful laser measuring machines, we are able to digitize any object brought into play by our customers – regardless of whether the original is a piece of jewelry, furniture or an airplane.

From the measurement data we obtain through this data feedback, we create abstracted reliefs as well as true-to-original or scaled-down 3D sculptures up to the size of a complete automobile, depending on the customer’s wishes. Materials available include aluminum, steel, copper and quartz glass.

REFERENCES

TECHNOLOGY

Our 45 employees have two large production halls with around 30 machines at their disposal at the Ingolstadt location:

CNC-controlled 5-axis machining centers and laser systems as well as hydraulic and deep-drawing presses and digital 3D measuring machines in an air-conditioned measuring room.

Together, they allow the production and machining of highly complex and filigree components, tools and fixtures.

In addition, there are CAD/CAM workstations for efficient processing of digital data.

TECHNOLOGY

Our 45 employees have two large production halls with around 30 machines at their disposal at the Ingolstadt location:

CNC-controlled 5-axis machining centers and laser systems as well as hydraulic and deep-drawing presses and digital 3D measuring machines in an air-conditioned measuring room.

Together, they allow the production and machining of highly complex and filigree components, tools and fixtures.

In addition, there are CAD/CAM workstations for efficient processing of digital data.

LOCATION

R. Riemensperger mechanische Werkstätte GmbH

Schütterlettenweg 6

D-85053 Ingolstadt

LOCATION

R. Riemensperger mechanische Werkstätte GmbH

Schütterlettenweg 6

D-85053 Ingolstadt

COMPANY

The foundation of R. Riemensperger mechanische Werkstätte GmbH took place in 1990 with eight employees in Ingolstadt by taking over the business activities of the company Ruland.

After the first ten successful years of operation, we not only had a wide variety of CNC-controlled machines and a team of 45 employees.

We had also moved into our new premises on Schütterlettenweg and had been named a Preferred Supplier by BMW Motorsport (F1).

Thanks to the craftsmanship of our employees and the cutting-edge technology we use, we are now a sought-after partner in all sectors of industry that demand high-precision components and uncompromising quality.

COMPANY

The foundation of R. Riemensperger mechanische Werkstätte GmbH took place in 1990 with eight employees in Ingolstadt by taking over the business activities of the company Ruland.

After the first ten successful years of operation, we not only had a wide variety of CNC-controlled machines and a team of 45 employees.

We had also moved into our new premises on Schütterlettenweg and had been named a Preferred Supplier by BMW Motorsport (F1).

Thanks to the craftsmanship of our employees and the cutting-edge technology we use, we are now a sought-after partner in all sectors of industry that demand high-precision components and uncompromising quality.

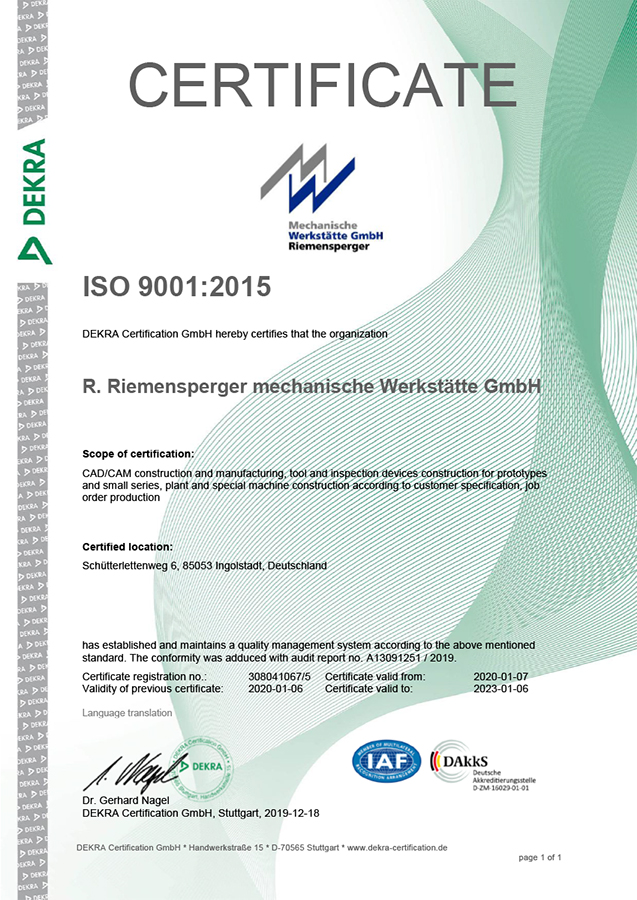

QUALITY

We ensure the quality of the components, tools and fixtures we manufacture in a variety of ways. On the one hand, our company works with a quality management system certified according to DIN EN ISO 9001:2008.

On the other hand, we use a range of CNC-controlled machines that allow micrometer-precise machining of the workpieces. And finally, thanks to our optical & digital 3D measuring machines, we are able to document the perfection of our work.

Because: quality is the opposite of coincidence.

QUALITY

We ensure the quality of the components, tools and fixtures we manufacture in a variety of ways. On the one hand, our company works with a quality management system certified according to DIN EN ISO 9001:2008.

On the other hand, we use a range of CNC-controlled machines that allow micrometer-precise machining of the workpieces. And finally, thanks to our optical & digital 3D measuring machines, we are able to document the perfection of our work.

Because: quality is the opposite of coincidence.

CERTIFICATION

Since 2004 we are certified according to

DIN EN ISO 9001:2008 certified.

Karriere

CNC Fräser - Ab sofort!

CNC Programmierer - 01.01.2021

Vertriebsmitarbeiter - 15.03.2021

Karriere