PROTOTYPING

PROTOTYPING

Quality close to series

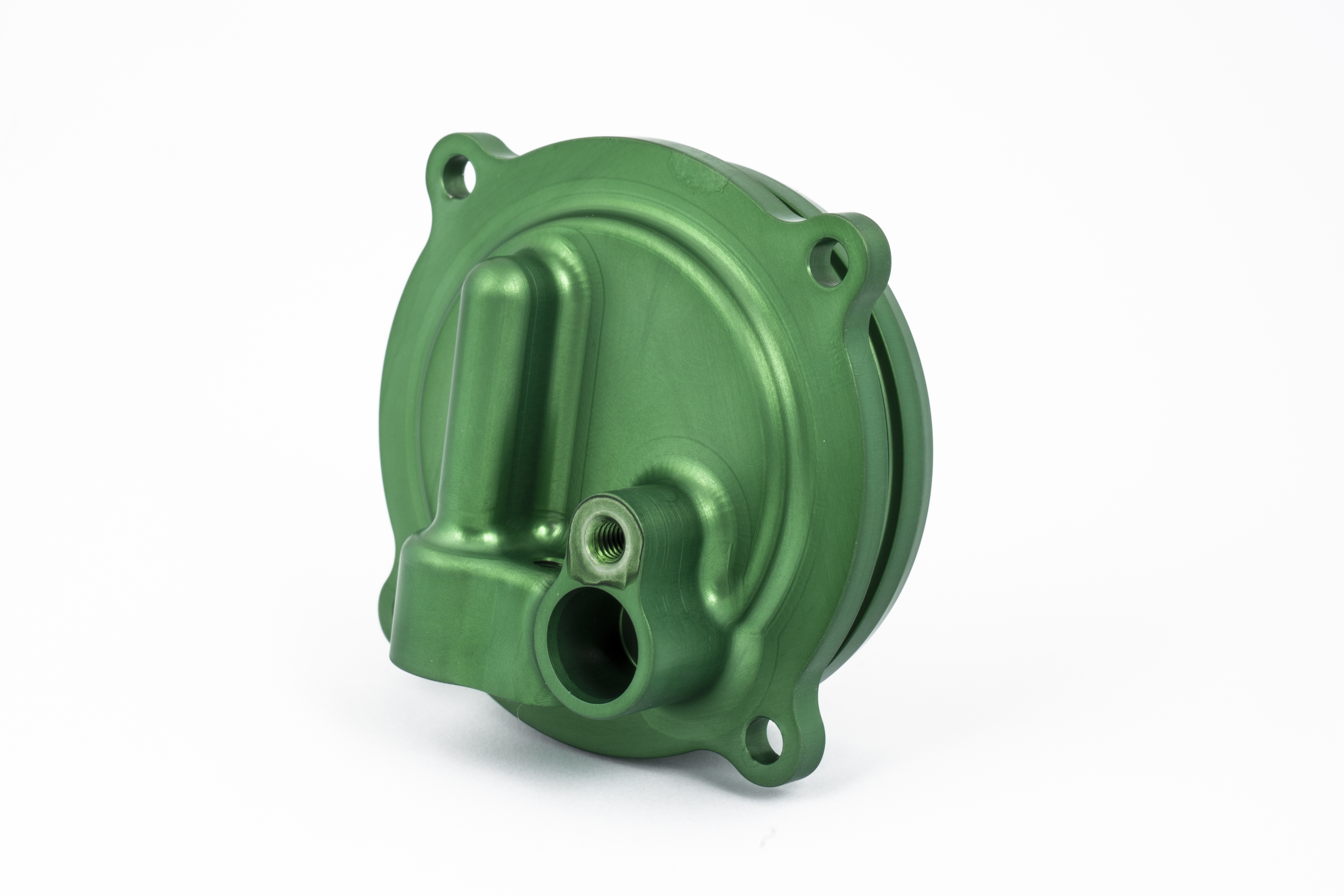

Prototypes are indispensable when it comes to making all the technical properties of a component qualitatively verifiable before it goes into series production. The early testing options allow both early qualification and test runs to be carried out with the components or assemblies.

We supply individually customized prototypes whose quality is just as close to series production as the associated manufacturing steps, despite short production times. In this way, potential savings can be identified at an early stage and incorporated into the series production processes.

Thanks to the many years of experience of our 45 employees and with the help of our ultra-modern machinery, we are able to carry out all the steps required to produce a prototype under one roof. This high level of vertical integration allows us to act quickly and flexibly and also ensures short delivery times for our customers.

Manufacturing example: Swirl element

Task:

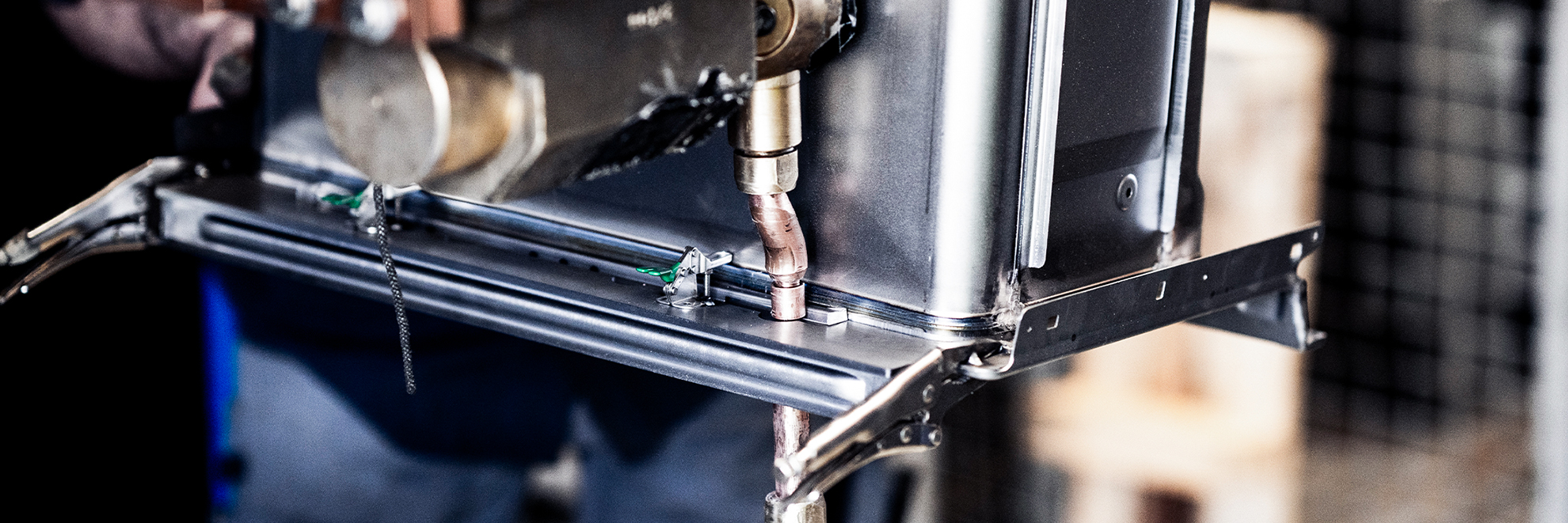

Using a given 3D digital model, we developed prototype tooling and fixtures for manufacturing a swirl element used in exhaust technology.

Challenge:

Manufacturing a complex component solely by forming and pressing a 2D stainless steel sheet.

Solution:

Laser cutting, pressing and forming of the 1.6 mm thick blank to the raw cone contour was already followed by 3D final trimming. This was a particular challenge because the final dimensional accuracy in terms of trim could only be achieved with further stamping stages. Special pressing tools finally made it possible to change over all the wing surfaces.

EXAMPLES

OTHER COMPETENCIES

Prototyping

We supply products in near-series quality. With processes that anticipate series production and thus enable early inspections and test runs. With a high vertical range of manufacture that ensures short delivery times.

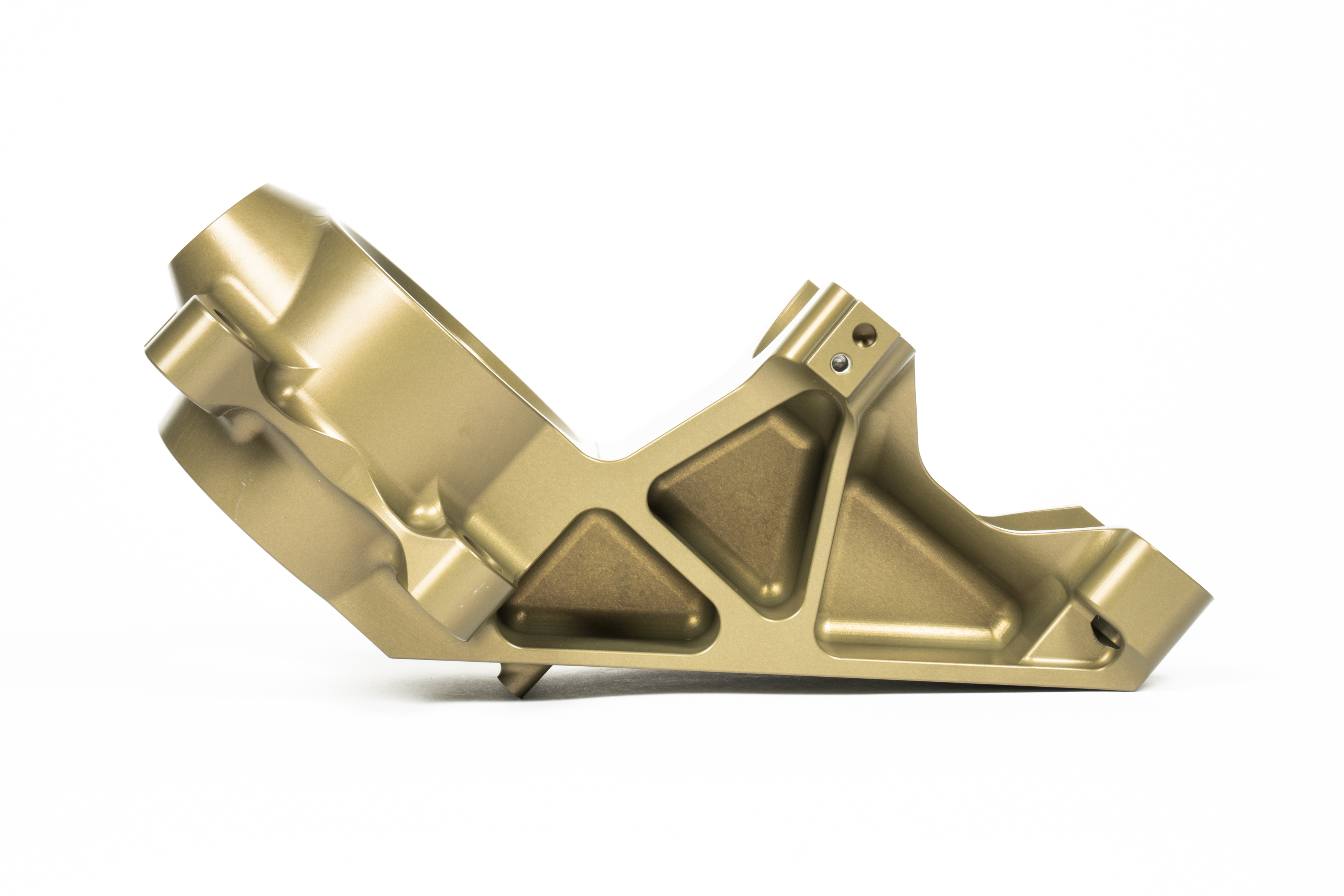

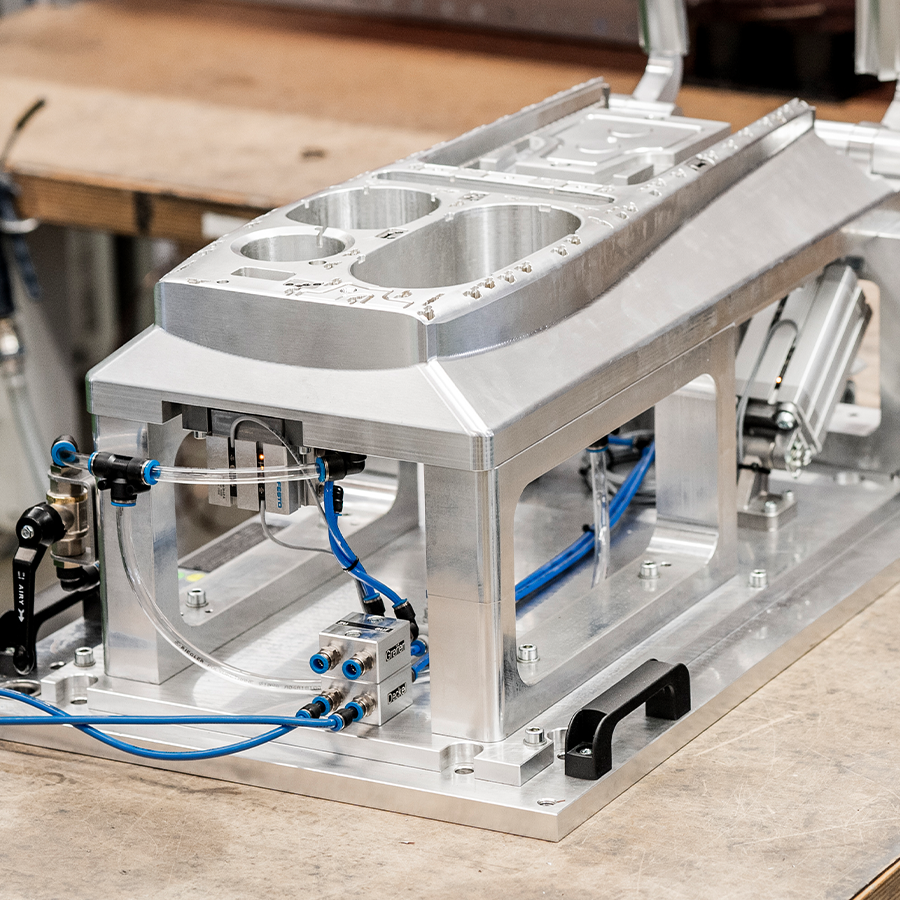

Forming Technology

We provide the desired shape. With project-specific molds and fixtures as well as hydraulic- and deep-drawing presses that enable the precise molding of even complex components.

Laser Technology

We cut and weld with short lead times. With large powerful 5-axis laser cutting machines that ensure consistent high quality when processing sheets of different materials and thicknesses.

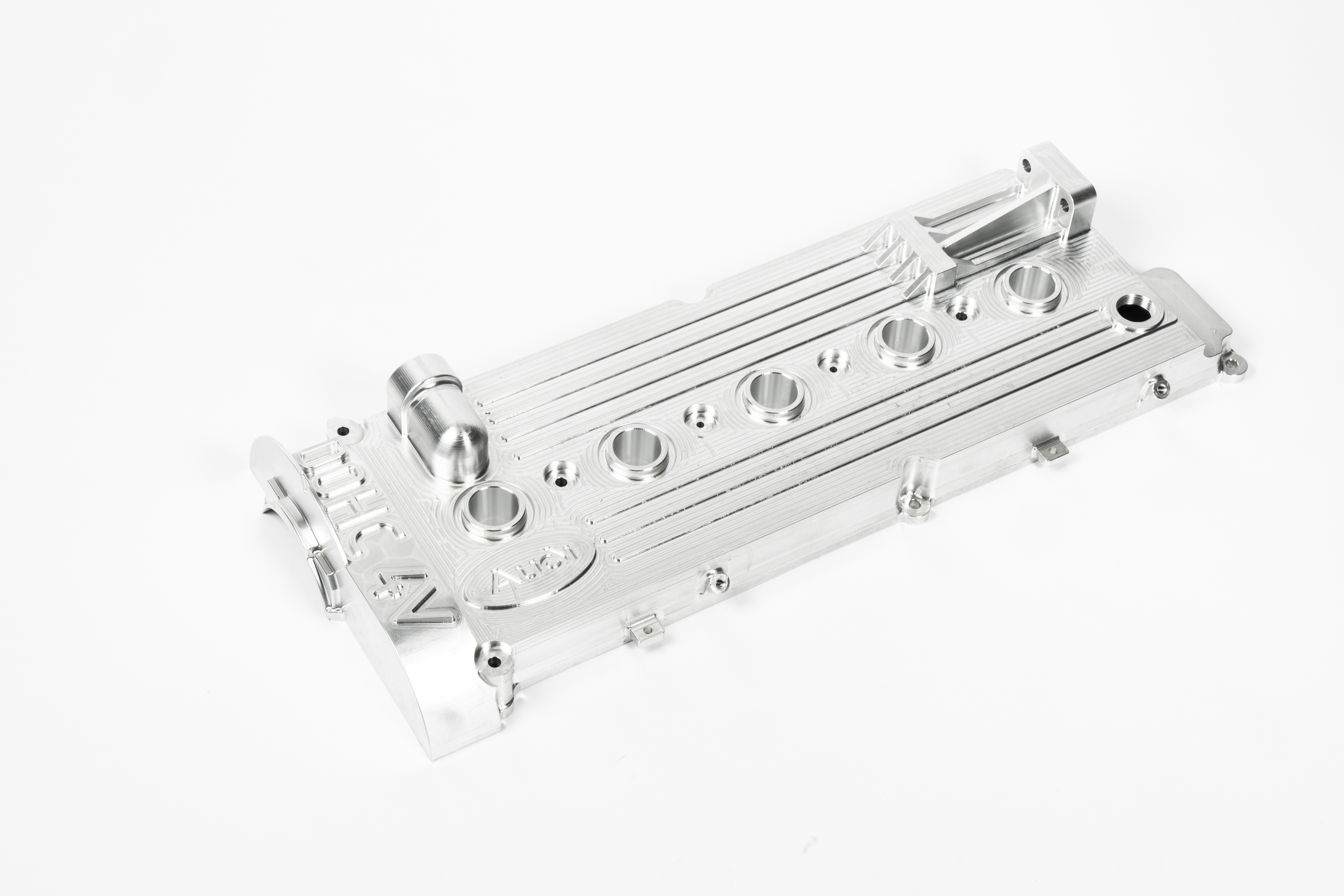

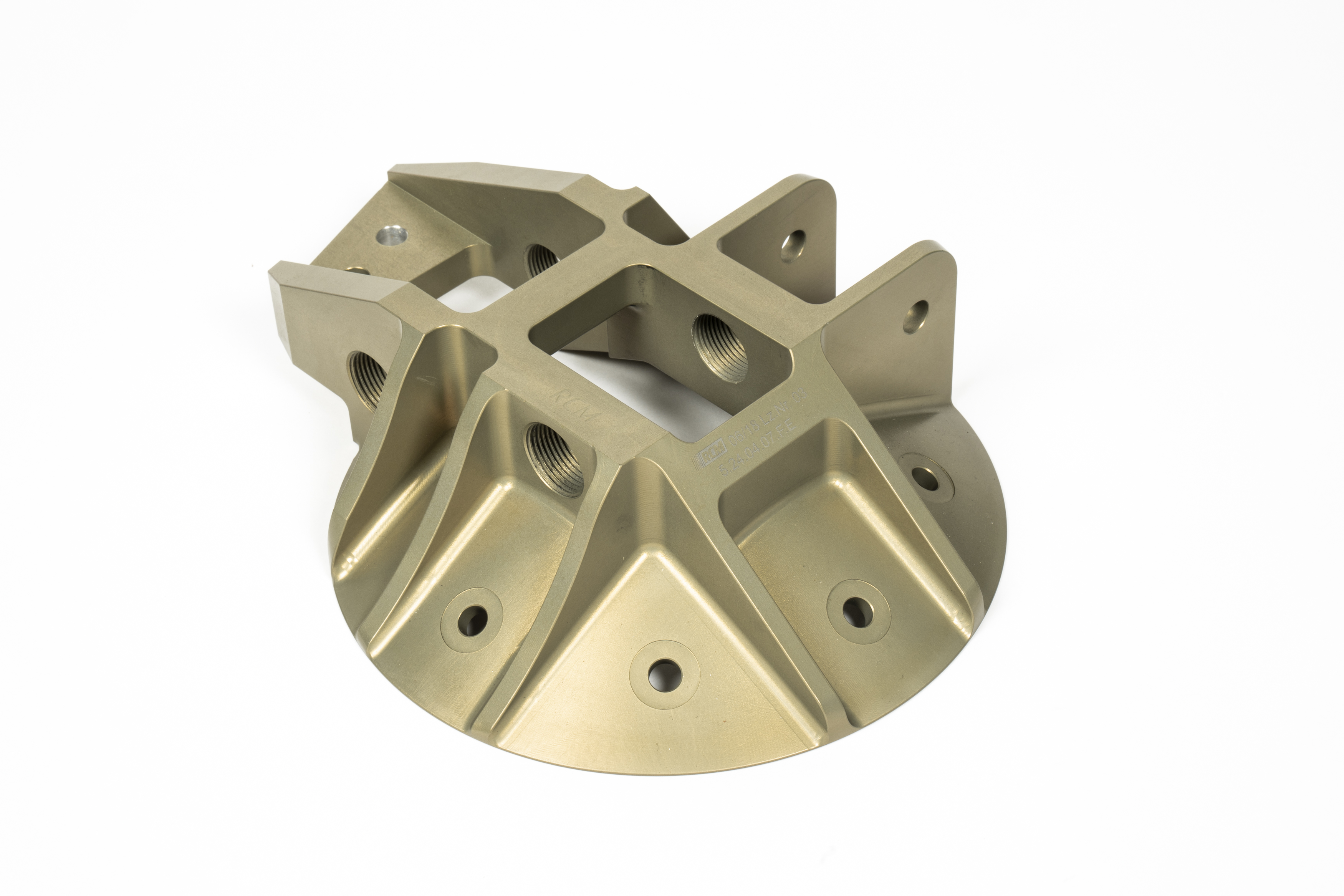

Toolmaking

We develop tools and fixtures adapted to the project requirements. For exceptionally precise components with flatnesses of ± 3 µm, parallelism of < 1/100 and surface finishes of Rz 2.

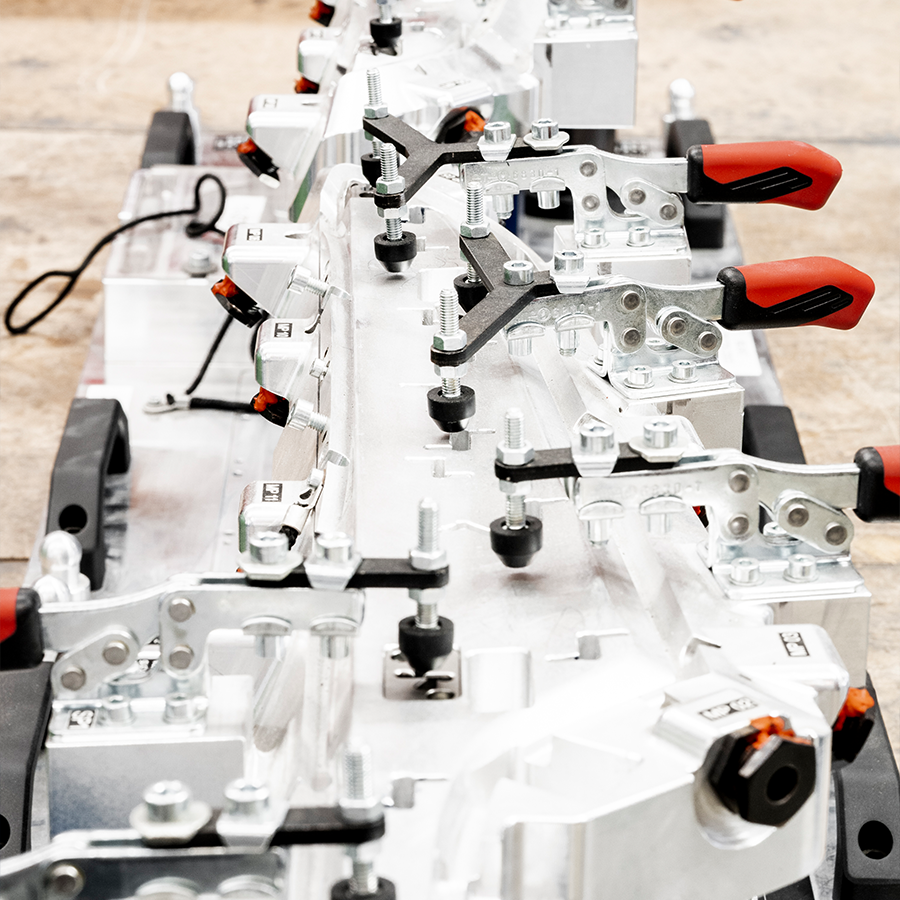

Gauge construction

We are precise and manufacture measuring fixtures as well as inspection gauges and equipment made of steel, aluminum and lightweight materials. For precise recording and inspection of components.

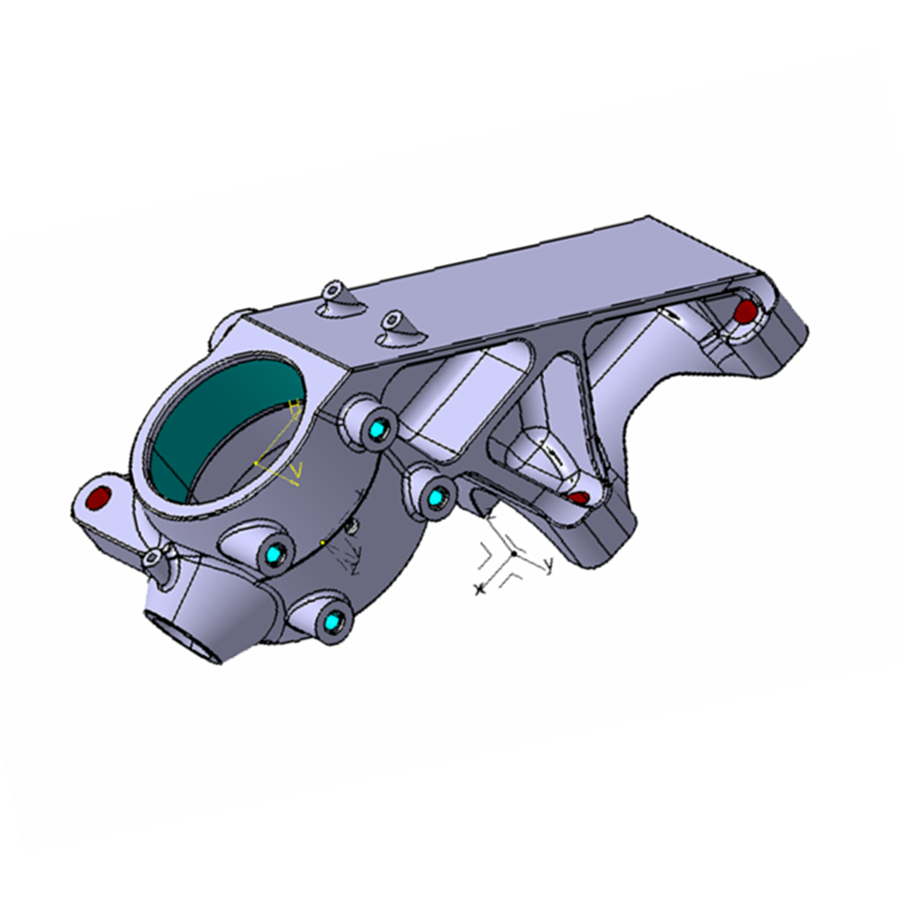

Construction

We work digitally. With modern CAD/CAM workstations, secure data transfers and all common software formats. For a production-oriented and efficient manufacturing sequence of parts and components.