LASER TECHNOLOGY

LASER TECHNOLOGY

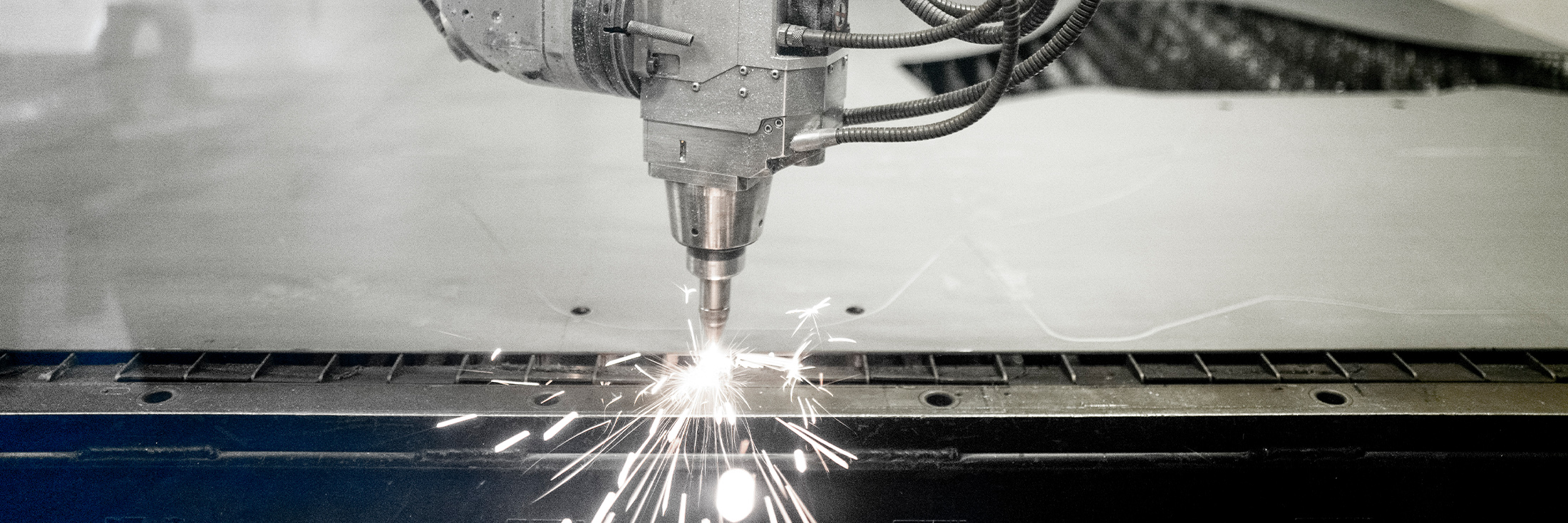

Cutting and welding

High-precision 3D laser cutting is mainly used where complex two- or three-dimensional outlines and particularly precise and fast machining are required. This is an economical process without high tooling costs, which is why it is particularly suitable for the construction of prototypes, pre-series and small series.

With the help of a 5-axis laser system with a processing area of 3000 x 1500 x 750 mm, we are able to cut and weld even large sheets of different materials and thicknesses in short processing times and with consistent quality.

For the individual marking of components according to the ideas of our clients, we also have a special marking laser.

Manufacturing example: Microwave

Task:

For a kitchen appliance manufacturer, we produced a prototype small series for the modularly designed cooking chambers of multifunctional ovens, microwave ovens and steam ovens.

Challenge:

Precise, airtight laser welding of sheet steel followed by leak testing.

Solution:

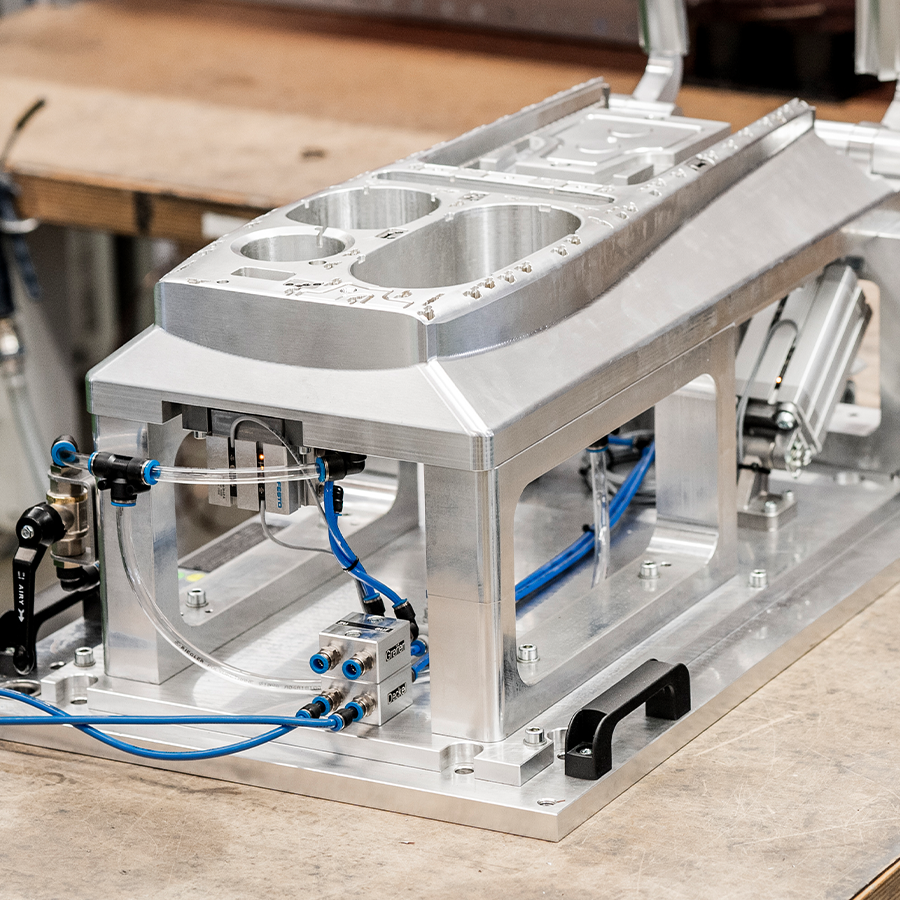

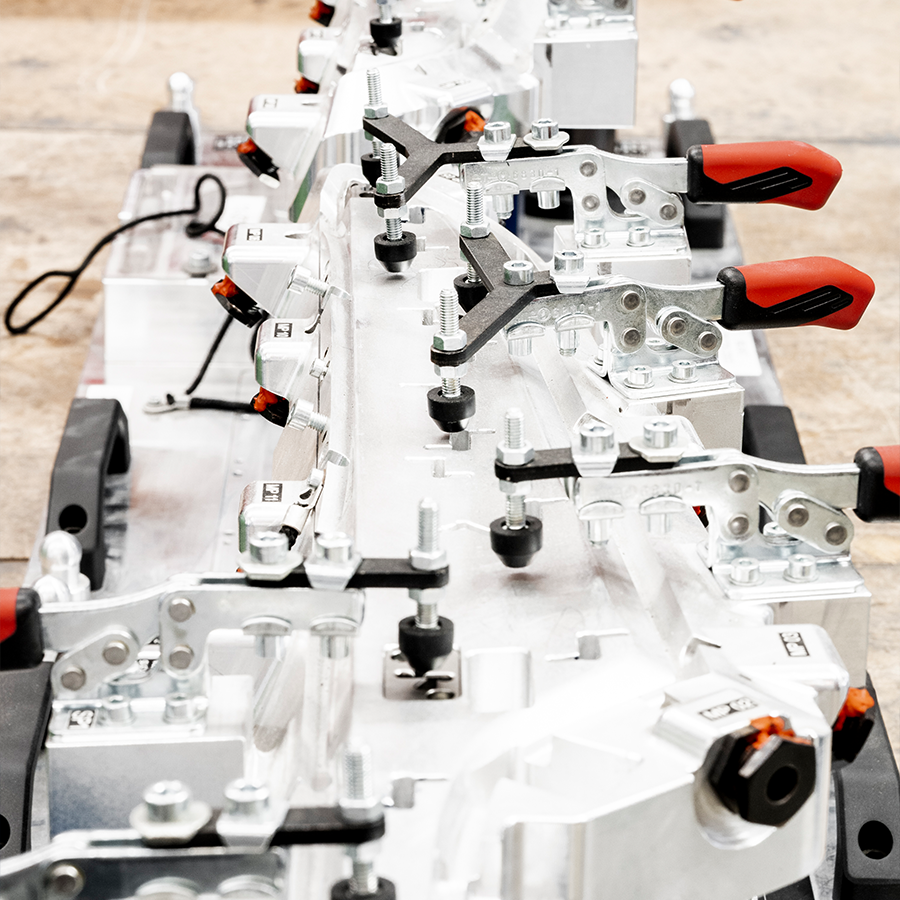

After laser cutting and forming the 2,5 mm thick steel sheet blanks, the components were mounted and fixed on a frame fixture designed and manufactured by us. This laser device had to ensure the absolutely tight fit of the components during resistance welding without restricting the laser head in its movement profile.

OTHER COMPETENCIES

Prototyping

We supply products in near-series quality. With processes that anticipate series production and thus enable early inspections and test runs. With a high vertical range of manufacture that ensures short delivery times.

Forming Technology

We provide the desired shape. With project-specific molds and fixtures as well as hydraulic- and deep-drawing presses that enable the precise molding of even complex components.

Laser Technology

We cut and weld with short lead times. With large powerful 5-axis laser cutting machines that ensure consistent high quality when processing sheets of different materials and thicknesses.

Toolmaking

We develop tools and fixtures adapted to the project requirements. For exceptionally precise components with flatnesses of ± 3 µm, parallelism of < 1/100 and surface finishes of Rz 2.

Gauge construction

We are precise and manufacture measuring fixtures as well as inspection gauges and equipment made of steel, aluminum and lightweight materials. For precise recording and inspection of components.

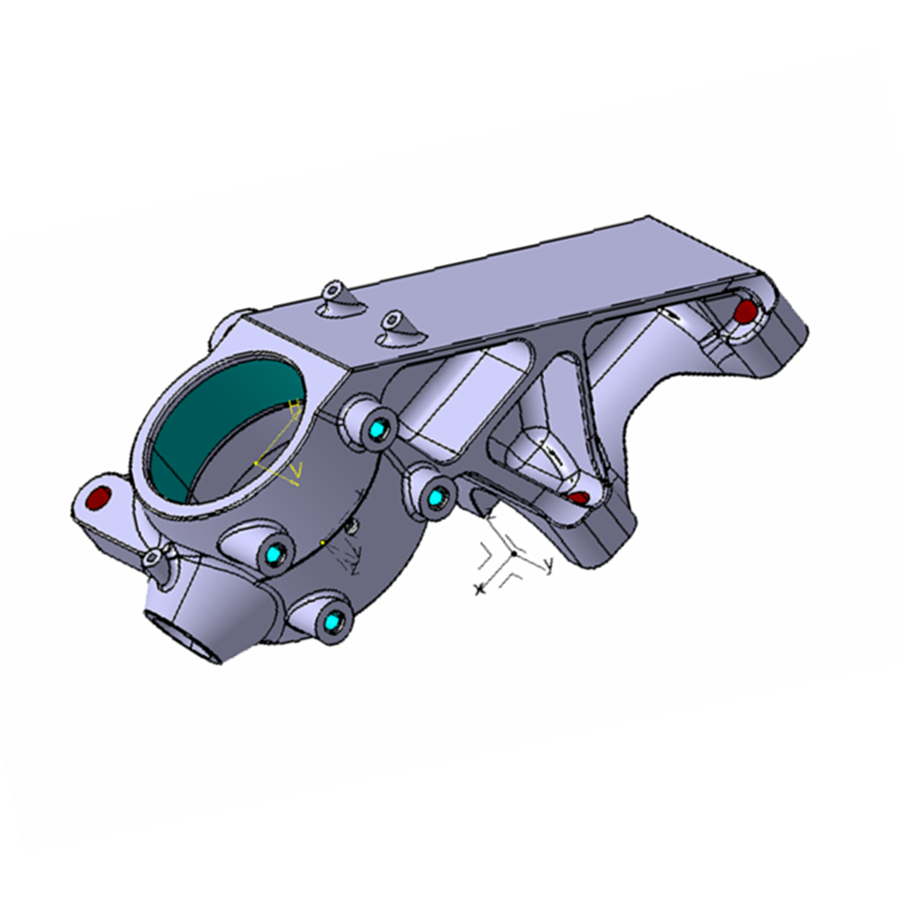

Construction

We work digitally. With modern CAD/CAM workstations, secure data transfers and all common software formats. For a production-oriented and efficient manufacturing sequence of parts and components.