FORMING TECHNOLOGY

FORMING TECHNOLOGY

Get into the right shape

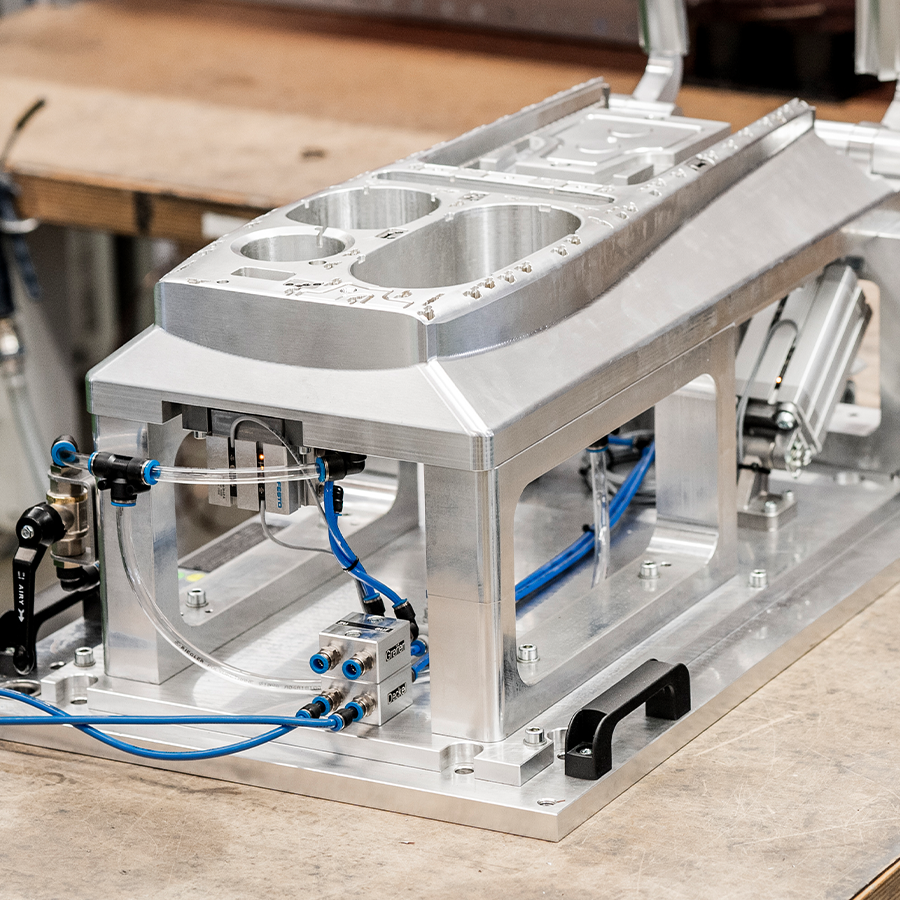

Our hydraulic and deep-drawing presses with a pressure rating of up to 3,500 kN can be used to form sheet metal – for example, steel, stainless steel, aluminum or brass – without cutting, so that even complex component geometries can be produced. In addition, large-format machining tables and rams allow a wide range of machining options and the implementation of high quality requirements.

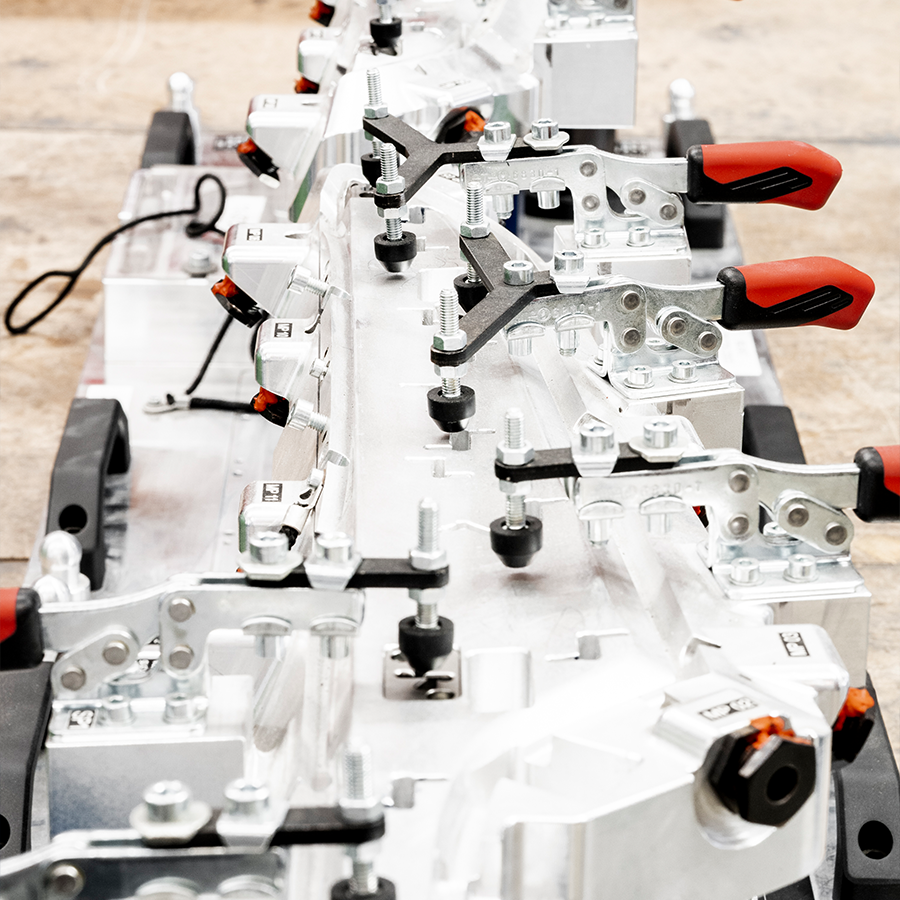

As a handicraft business with a high degree of vertical integration, we are able to manufacture almost all the forming tools and jigs required for deep drawing, pressing or bending ourselves.

Our efficient production technology also allows us to subsequently rework the formed workpieces using a wide variety of methods and to measure them for quality control.

Manufacturing example: seat shell

Task:

As part of a prototype development, we developed a process for building a highly stable, intricately shaped seat shell made of cold-rolled, 2,5 mm thick sheet steel.

Challenge:

Forming a higher-strength steel sheet with only 21% elongation at break – taking into account the maximum permissible material thinning.

Solution:

In a manufacturing process with only a few production steps in total, the main contour was first stamped with the corresponding curvatures. The subsequent intermediate trimming was followed by the resetting of the edges and the final trimming, which also included the laser cutting of the numerous holes and openings.

EXAMPLES

OTHER COMPETENCIES

Prototyping

We supply products in near-series quality. With processes that anticipate series production and thus enable early inspections and test runs. With a high vertical range of manufacture that ensures short delivery times.

Forming Technology

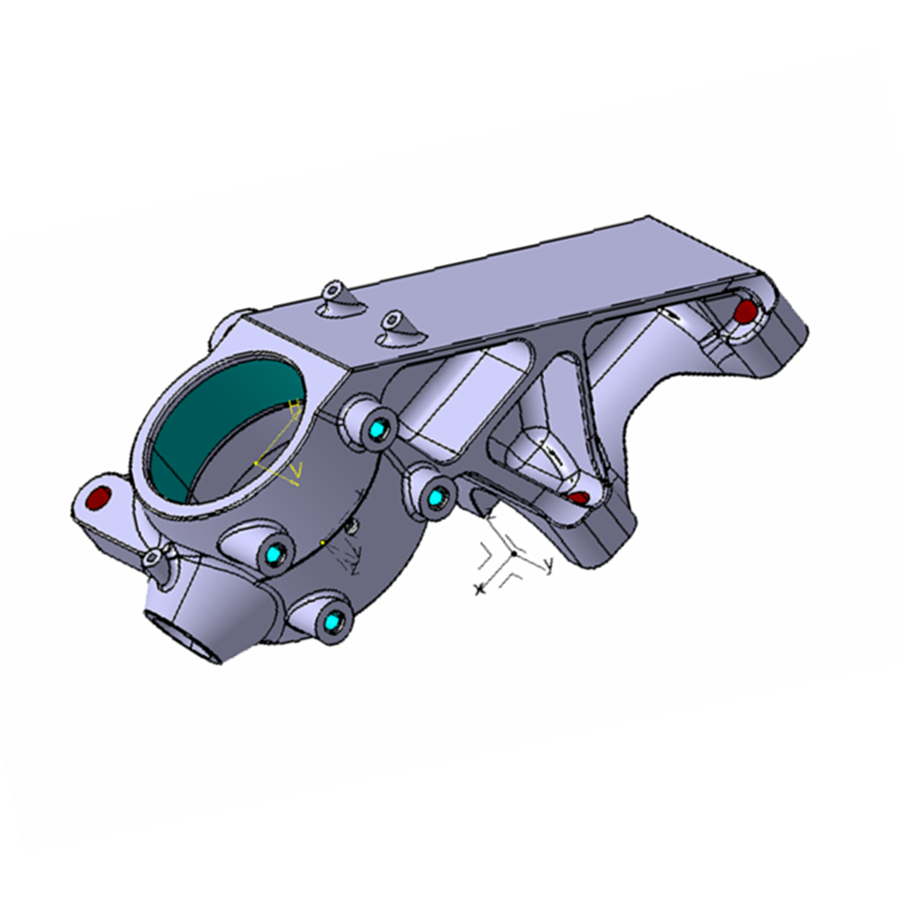

We provide the desired shape. With project-specific molds and fixtures as well as hydraulic- and deep-drawing presses that enable the precise molding of even complex components.

Laser Technology

We cut and weld with short lead times. With large powerful 5-axis laser cutting machines that ensure consistent high quality when processing sheets of different materials and thicknesses.

Toolmaking

We develop tools and fixtures adapted to the project requirements. For exceptionally precise components with flatnesses of ± 3 µm, parallelism of < 1/100 and surface finishes of Rz 2.

Gauge construction

We are precise and manufacture measuring fixtures as well as inspection gauges and equipment made of steel, aluminum and lightweight materials. For precise recording and inspection of components.

Construction

We work digitally. With modern CAD/CAM workstations, secure data transfers and all common software formats. For a production-oriented and efficient manufacturing sequence of parts and components.